Current news

MSK will be exhibiting at LogiMAT 2024

Read more

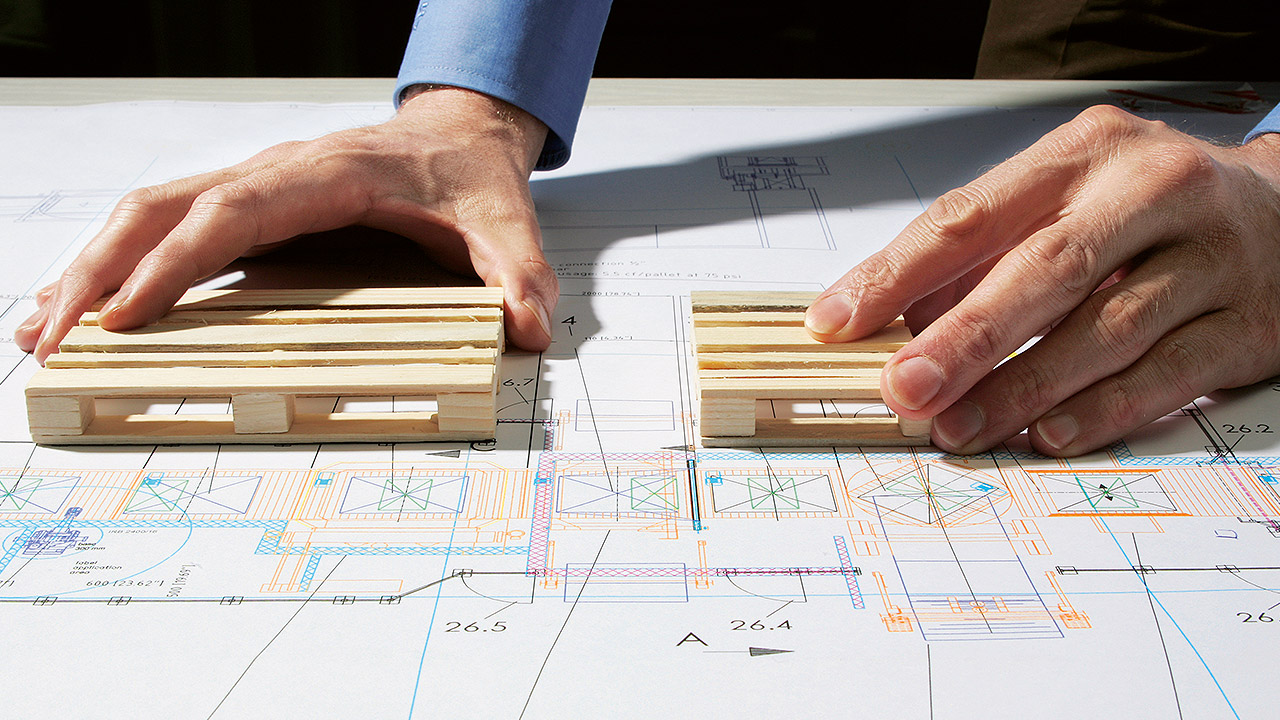

Right from the start, MSK has placed much emphasis on the conservation of resources. Since the foundation of the company, sustainability has been one of the main criteria for the development of a MSK machine.

Read more

MSK service is there for you around the clock. It includes everything to safeguard and increase the productivity of a MSK system. There are more than 50 engineers, technicians and specialists at your disposal.

Read more

Thanks to 3D animations and images, the operating software MSK EMSY allows an intuitive machine operation without extensive prior knowledge.

Read more

For over 40 years we have stood for progress and invention. We see ourselves as a strong partner to the industries and have collaborated on many pioneering patents.

Read more