Shrink wrapping for household appliances

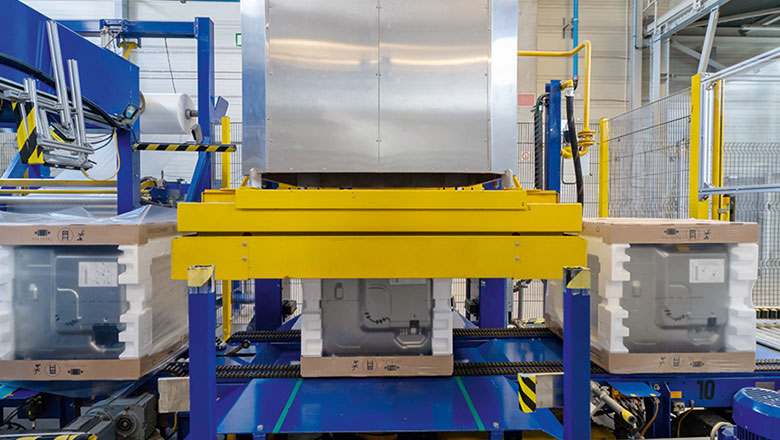

MSK pallet shrink wrap for household appliances

Efficient transport packaging

A clean, undamaged packaging in which the device is easily visible has been shown to reduce the rate of transport damage.

The transport packaging of household appliances such as washing machines, refrigerators, etc. consists of primary and secondary packaging. Regarding pressure sensitivity or stability it is possible that the primary packaging makes special demands on the film packaging. Contrariwise a certain secondary packaging method means that savings may be possible concerning primary packaging.

Highest transport safety and packaging flexibility with MSK shrink wrap

Shrink wrapping has, in the face of the manifold demands presented by the field of transport packaging, proved itself to be an excellent technology. It is the most commonly used and often also the most reliable pallet packaging procedure for the leading manufacturers of household appliances. In order to satisfy the specific requirements of your industry, an MSK hybrid system is also available.

Advantages:

- High transport safety for your product

- Modern product marketing

- Excellent display effect (ClearView effect) with high protection

- Problem-free use of perforated films for the prevention of condensation

- Energy and film costs savings through thinnest films

- Fully recyclable film, and films made of recycled materials available

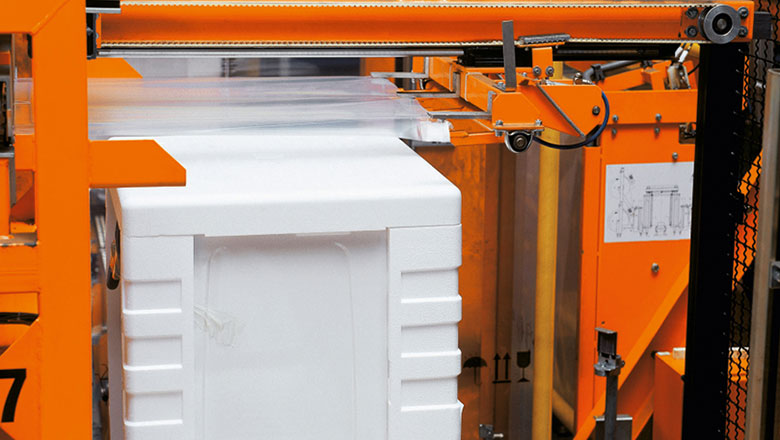

Highly flexible MSK shrink-film sleeving system - MSK Flowtech

Specifically for cost-efficient packaging of very different product formats in the laundry sector, MSK has designed the film sleeving process MSK Flowtech.

Advantages:

- Particularly suitable for the packaging of different product formats (length, width)

- Film savings through the use of thinner films and precise film sleeves for each individual product

- Easy film handling due to horizontally mounted film rolls

- Highest packaging performance of up to 400 products per hour (depending on product)

- Availability of fully recyclable films, and films made of recycled materials

Smooth packaging all around

The MSK Flowtech obtains an ideal packaging result for highly differing product dimensions. The machine recognizes the product sizes fully automatically, and supplies a tailor-made film sleeve.

Top sheet applicator

When dealing with products without slide-on cardboard to protect the top side of the product, top sheet applicators provide a perfectly sized top sheet film thanks to automatic product recognition.

Customized film sleeve

The film sleeve is put tightly around the product, using a minimum of film per product. Thanks to the sleeve adjusting to the individual product height, pre-shrinking of the corners is not necessary.

Horizontal film rolls

Horizontal film rolls allow the use of film roll diameters of up to 1,000 mm. They offer easy handling and prolong the replacement intervals significantly.

Clean film cutting thanks to a blade

Using a blade, film can be cut easily with no odours. In comparison with the thermal alternative, it allows much longer replacement intervals.

Three-size system

In option, the MSK Flowtech can be equipped with three film rolls. This possibility optimizes the amount of film used as well as the packaging result especially when having various load heights such as in the laundry sector.

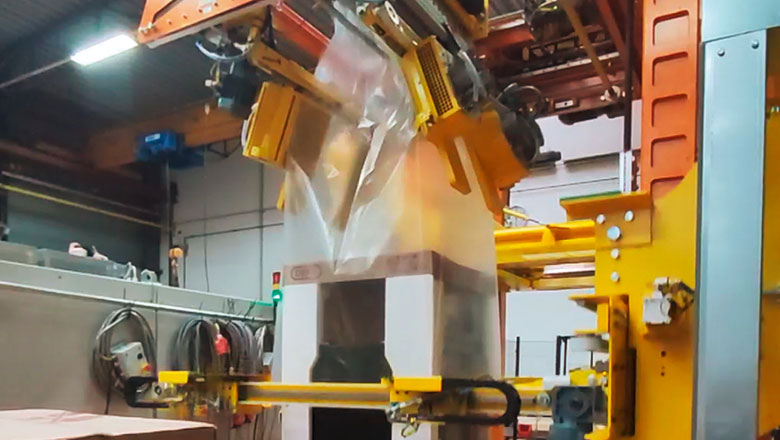

MSK shrink hood applicator for changing formats - MSK Multitech

With the shrink hood system MSK Multitech various product formats can be packaged flexibly and in a small space.

Advantages:

- Packaging of changing product dimensions with up to 4 different film formats or film thicknesses

- Film savings through the use of thinner films as well as precise and individual assembly of the film hood

- Low space requirements due to compact design

- Easy maintenance due to lowerable machine head

- Fully recyclable film and films made of recycled materials possible

- High packaging performance of up to 260 products per hour (depending on product)

Customized film hoods

Large amounts of film are saved because each individual film hood is precisely cut to size. The MSK coordinate process ensures that each hood is opened and applied product-specifically. The use of perforated films to avoid condensation is also possible.

Save space with our compact model

Hood covering and shrinking can both be done at one place. This model is adapted for limited spaces and medium-level packaging performances.

Flexible and fast

As a line-up version, the MSK Multitech can process up to 260 products per hour. Product sizes that are still unknown today may already be packaged on an MSK machine tomorrow, as it can handle up to four different film sizes or thicknesses. Storing film rolls as packaging material, rather than as large boxes, saves a considerable amount of space.

Multi-format system with simple film roll change

MSK Multitech is capable of packaging varying product sizes with up to four different film formats or thicknesses. This allows for maximum flexibility with changing product sizes. The film roll replacement can easily take place outside of the safety fence.

MSK Safety Shrink-frames – protective of the products and the environment

MSK offers safe and sustainable shrink frame systems. The product-specific combination of a film sleeving system or a film hooding system and a MSK shrink frame system provides a cost-effective MSK packaging system for the transport packaging. Thanks to the use of the internationally known MSK Undershrink process - as developed by MSK - the tensile strength of the film is fully developed and provides the maximum possible transport stability of the wrapped household appliances on delivery. The process smoothes the film to far below the product. The products can be safely stacked, loaded and transported.

Advantages:

- Low energy consumption and optimal energy efficiency via heat recycling

- Product specific shrinking: automatic adaptation of the warm air flow to each product size and shrink zone

- Additional energy savings when used in combination with the MSK Covershrink

- Modern and certified Safety System (DVGW certified) with air and gas monitoring

- Maintenance-free MSK heating elements with 5-year warranty

- Available in gas or electrical version

MSK Covershrink offers up to 40% energy savings

MSK shrink packaging systems can be equipped or retrofitted with the patented energy saving module MSK Covershrink. The MSK Covershrink, depending on the film thickness and product format, offers an energy saving of up to 40%.

Shrink safely with MSK

Thanks to MSK special air system, the film keeps its elasticity and fatigue resistance and enables energy efficiency.

Opt for an electric heating system

MSK shrink technology is also available as electric version with the MSK Corritech with eCovershrink. It is combining high load stability and sustainability.

Well-equipped for the future

Future product sizes that are still unknown today can be packaged inexpensively tomorrow, using MSK shrink packaging systems. MSK machines apply safe shrink processes at low temperatures and thus package products systematically and carefully.