Simplified machine control

Networked and smart machine processes with MSK EMSY 6

MSK EMSY 6 is a new generation of the MSK visualization software which establishes the foundation for networked and smart machine processes towards fully automated intralogistics along the lines of Industry 4.0. Through communication with ERP systems and peripheral devices the software offers a high level of process automation in the area of pallet logistics, allowing networked and standardized control of all systems related to pallet handling.

The sixth generation of the MSK EMSY software features new options and enhancements:

- High data security through automated backups

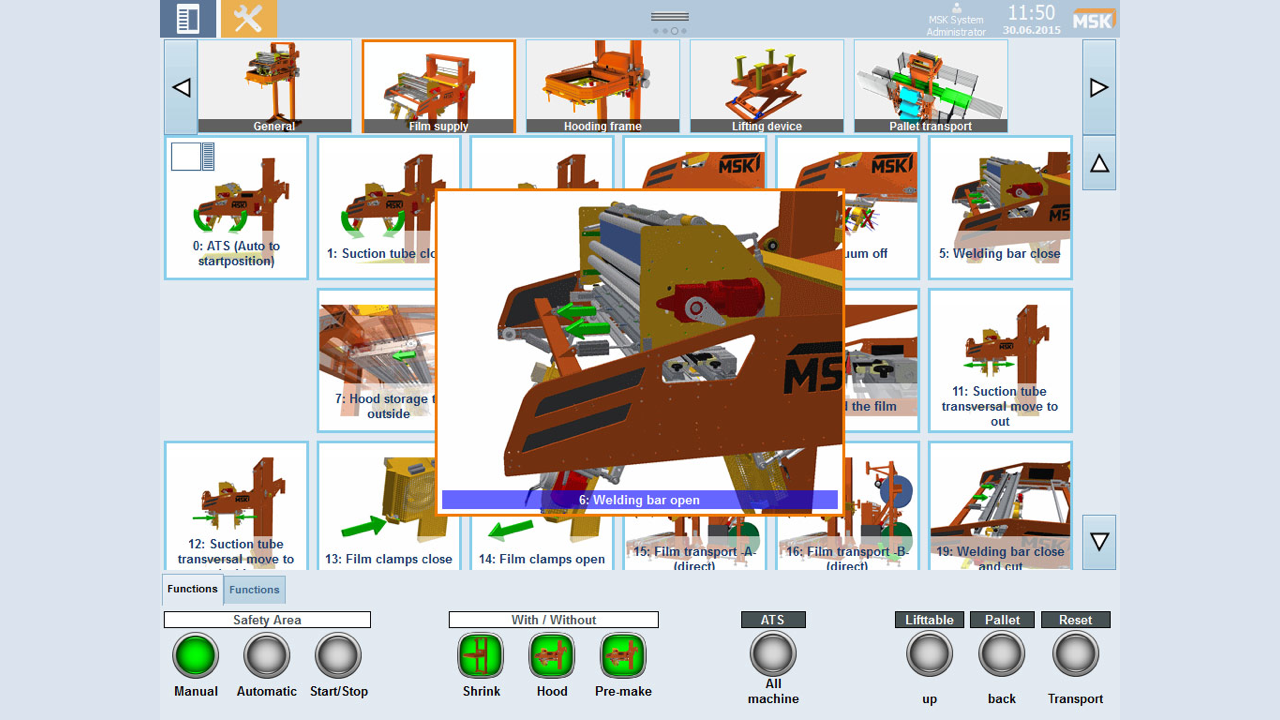

- Parameter-setting with graphic support

- Parameter change history

- Proactive maintenance management with calendar function

- Quick troubleshooting through display of potential causes and solutions

- Secure RFID user identification

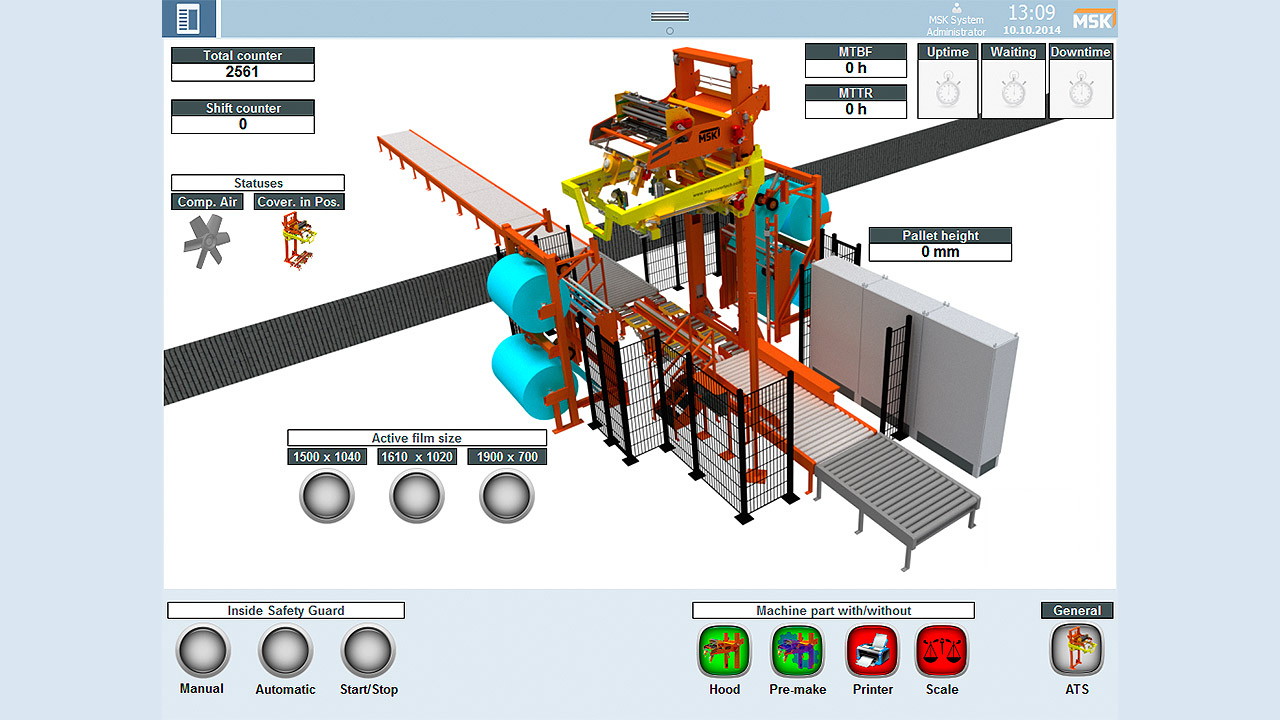

Simple machine control

In its sixth generation MSK EMSY (Electronic Management System) is a unique visualization system which makes it easy to control complex palletizing, packaging and conveyor systems. It allows graphic operation with manual and automatic functions, it records operating data, manages parameter profiles, keeps statistics, visualizes processes, supports proactive maintenance, allows remote maintenance through a 24h VPN hotline service, makes troubleshooting easier, offers options for internal information networking, and much more.

A picture says more than a thousand words

The procedures for conveying, palletizing and packaging technology are always becoming increasingly more demanding. In order to meet current challenges, operators have to give processes their full attention. With the new software EMSY 6 these same processes run almost by themselves.

Operator control and visualization software

MSK EMSY 6 facilitates communication between man and machine. Information from all types of peripheral devices are managed by the software and can be forwarded to your system (MES, ERP, SCADA etc.). The software allows interfaces to all known PLC controls and operating systems.

The MSK EMSY 6 customer editor allows you to optimally adapt the machine controls to your own specific needs.

High operator-friendliness

The clearly structured, intuitive user interface, easy-to-understand status information as well as a user support for almost all functions of the EMSY 6 means reduced training time for operators and makes troubleshooting easier.

NEW: Smart complete systems with MSK EMSY analytics

The MSK EMSY analytics software was developed by MSK specifically for the glass industry. At the Cold End of glass production the software interconnects the data of all machines controlled by EMSY and makes it available for centralized monitoring and planning. MSK EMSY analytics provides transparency in overall plant efficiency and identifies options for increasing efficiency. The software includes centrally controlled automated backups for high data security, and centralized proactive maintenance management functionality.

Advantages:

- Centralized control with real-time data

- Analysis of the entire system based on networked statistics

- Automated backups for high data security

- Increased efficiency