MSK Unwrapping systems

Fully automated unpacking of wrapped and strapped pallets with the MSK Defotech unwrapping system and the destrapper MSK Destraptech

Especially the unpacking of high pallet loads is hazardous and requires special work safety procedures. Fully automatic defoilers and destrappers make an effective contribution to greater safety: The film unwrapping system MSK Defotech and the destrapper MSK Destraptech reduce manual intervention by staff to a minimum thus making an effective contribution to more work place safety. Thanks to the fully automatic unwrapping process products will not slip and fall on people's heads.

MSK is a specialist in systems for the automated unpacking of pallet loads and has been supplying the beverage industry in particular with the fully automatic MSK Defotech defoiling system for decades. The long-standing customer base includes well-known manufacturers such as AB Inbev, Absolut Vodka, Arca Continental, Ardagh Glass, Bavaria, Diageo, Evian, Heineken, KHS, Krones, Mark Anthony Brewing, Nestlé, P&D, Sidel and Quinn Glass.

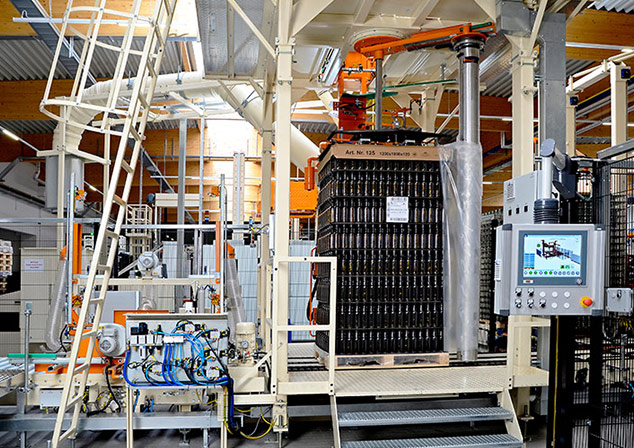

Fully automatic defoiling system MSK Defotech

MSK offers, with its patented MSK Defotech a fully automatic unwrapping system that can unwrap pallet loads safely and in a confined space. The machine is available as version for shrink wrapped, spiral-stretch wrapped or stretch-hood wrapped pallets or for a combination of these applications.

The MSK Defotech also provides an efficient solution for increased production speeds and will lead to the reduction of personnel costs in multi-shift operations. The machine fits seamlessly into the existing production flow and can also be used with upstream and downstream machines.

Advantages:

- Increased safety when unpacking for personnel and product

- Higher unpacking speeds - automatically unpacks up to 60 pallets per hour

- Savings on personnel costs

- Enables total recycling of film

- Space-saving footprint

Defoiling in a confined space

The MSK Defotech is also suitable for restricted space conditions as it unwraps the pallets in the smallest possible space. Thanks to a special unwrapping principle it works in a very gentle manner. Where necessary, the flexibly mounted winding spindle gently pushes loads back to the correct position.

Total recycling of film

After unwrapping, the MSK Defotech automatically prepares films for recycling through a special film removal system. When using homogeneous film types, these can be completely recycled – an advantage that contributes to the profitability of the production line.

Space-saving storage utilizing baling presses after the removal of the film

Utilization of a supplementary baling press means that the film removed is pressed to bales for subsequent recycling. This enables a significant storage space saving.

Fully automatic destrapper MSK Destraptech

Incoming pallet goods that are secured with straps are automatically unstrapped by the MSK Destraptech, at speeds of up to 45 pallets per hour. The system allows high production speeds, enhanced work safety, and the reduction of personnel costs. The machine can act as stand-alone solution or be integrated in automated pallet handling systems. Particularly when used together with the MSK Defotech unwrapping machine, it can function as a fully automated unpacking system for pallet loads.

ADVANTAGES:

- Increased work safety when unpacking pallets

- Higher unpacking speeds - automatically unpacks up to 45 pallets per hour

- Reduction of personnel costs

- Space-saving footprint

- Suitable for vertical strapping

- Automatic shredding of straps

Flexible and powerful

Thanks to a special MSK method of severing the straps on the upper side of the pallet load, the processing of up to 45 pallets per hour is possible, even with multiple straps, different strap patterns, and mixed production. The MSK Destraptech can remove up to four transverse and four longitudinal straps per unpacking cycle. The standard model of the machine is designed for one pallet size. If required, it can be designed to handle up to three different pallet formats. Even under or over palletized pallets can be processed. Pallet transport can be both longitudinal or transversal in orientation.

Space-saving disposal

With the help of a powerful shredder, the removed straps can be collected in a space-saving way, and sorted in homogenous types for disposal.