Pallet conveyor systems for building materials

MSK Conveying systems for pallets and non-palletized load units for the building materials industry

Fully automatic pallet handling from production to loading area

In order to convey building materials from a palletizing station or the production to the packaging system and continue to the truck loading area or into the pallet warehouse, pallet conveyors in the building materials industry have to meet a wide range of requirements. Unpackaged, unstable products on, as is often the case, damaged pallets require special conveyor transfer stations, furthermore the conveyor system must be able to cope with dusty and abrasive materials.

Combined with fully automatic fully automatic packaging systems MSK pallet conveyors work as an integrated transport system, controlled by the MSK software EMSY. Especially in the case of transportation to packaging systems the precise positioning of the conveyed goods can be cost saving because the packaging film size can be minimized.

Advantages:

- Tried and tested in the building materials industry for over 20 years

- Long-lasting premium components and robust constructions

- Special support elements for the transport of slippery and unpackaged material loads

- Development of individual solutions for pallet conveyor technology with special requirements

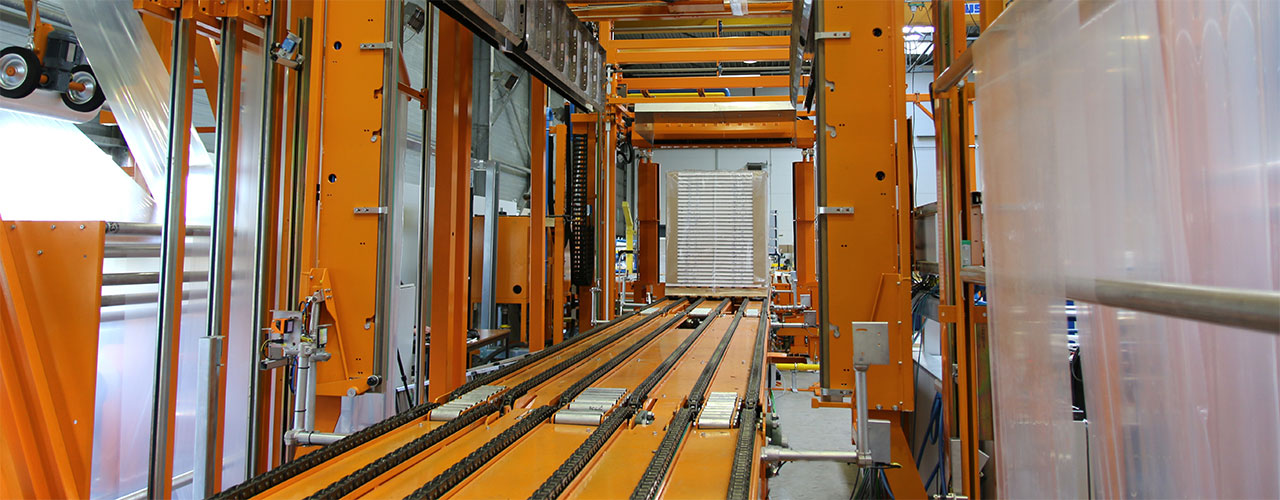

Stationary MSK pallet conveyors for the building materials industry

Conveyor systems for a wide range of requirements

The comprehensive MSK Transtech product program offers stationary conveying systems and pallet handling - for almost all applications and pallet formats in the building materials industry:

- MSK Roller conveyors

- MSK Chain conveyors

- MSK Plate conveyors

- MSK Shifting conveyors

- MSK Rotating elements

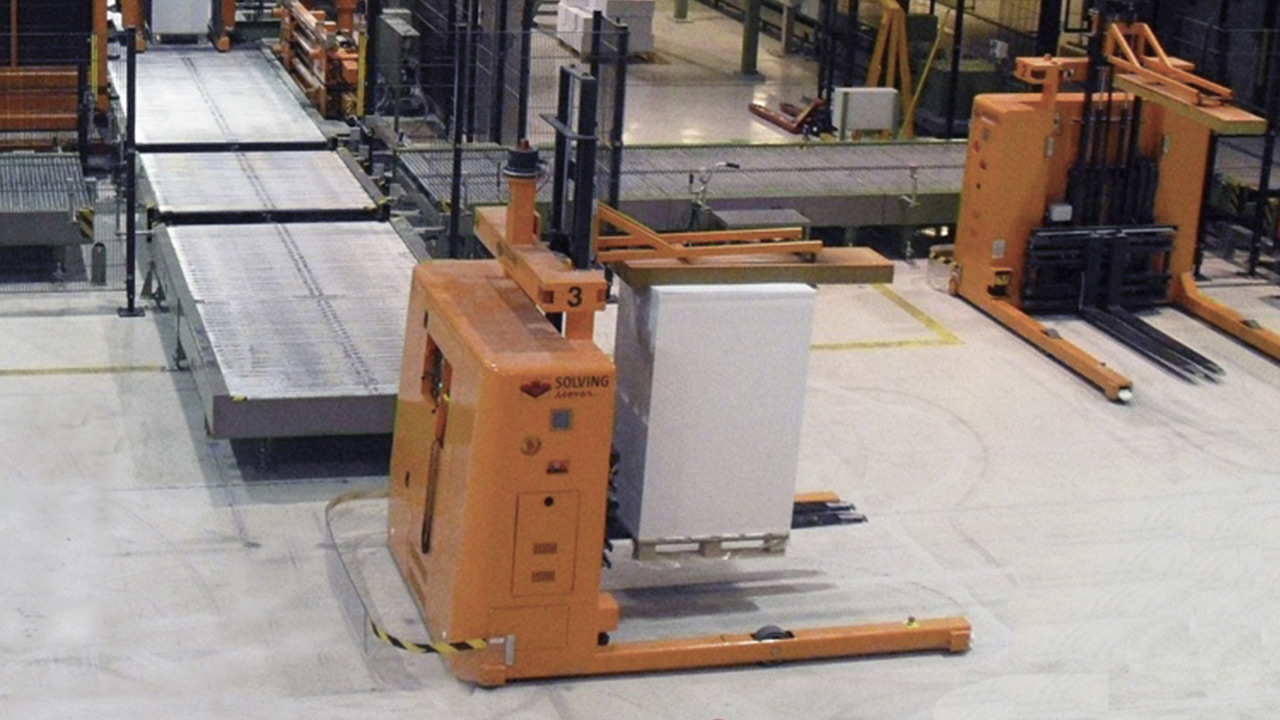

Mobile MSK shuttle cars for the building materials industry

Where the use of stationary pallet conveyors is not possible, forklift trucks are often used to transport packaged or unpackaged building material pallets. This is not only dangerous, it disturbs the flow of the production process and fork lift truck motors emit exhaust gasses.

An alternative is the use of mobile pallet transport systems, for a safe, quiet and automated production flow which additionally ensures that pallet specific data accompany the pallets to the warehouse. The mobile MSK conveying systems transport pallets or pallet-free packages from the production to the truck loading area fully automatically and without unpleasant forklift traffic. The necessary customized layout concepts are carefully worked out by experienced project engineers.

Solutions:

- Shuttle cars MSK Linktech

- Vertical conveyors

- AGV transport systems