MSK at LogiMAT 2026

Are you looking for a complete automated solution for your end-of-line? Optimize your productivity, reduce your packaging and labor costs and protect the environment - with one single partner MSK!

Our MSK specialists will be happy to advise you on individual and sustainable pallet logistics. We offer you complete systems for your intralogistics that cover the entire process from production, including palletizing up to load securing and conveying to the warehouse or truck loading from a single source - all controlled and logged by our EMSY software.

We look forward to welcoming you to LogiMAT in Stuttgart. You will find us in hall 7, booth 7A80. Arrange an appointment at sales@msk.de. We look forward to seeing you!

Unpacking made easy with the complete package from MSK

There is often undiscovered automation potential in the delivery of pallets and the subsequent feeding into the internal material flow with unpacking, depalletizing and transport to production and filling lines. MSK offers a complete package that is customized to your requirements. The MSK portfolio in this area includes the fully automatic MSK Defotech unwrapping system, a fully automatic MSK Destraptech destrapper, as well as gantry or robot-based depalletizing systems. The MSK Defotech unwrapper is available for all standard film packaging. Once the pallets have been unpacked, the MSK Defotech automatically prepares the film for recycling via a special film removal system. If the packaging films are collected by type, they can be completely recycled.

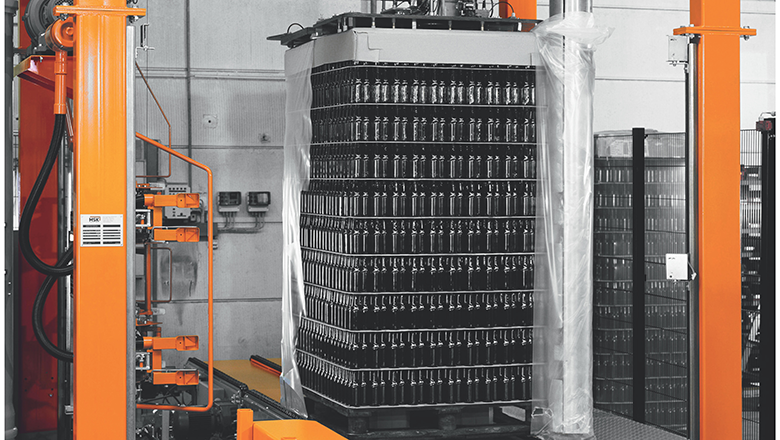

MSK palletizing systems for maximum flexibility and efficiency

MSK robot palletizers are all-rounders that operate in the tightest of spaces. In combination with individual end-of-arm tools, they are used for products from a wide range of industries. Everything is controlled and logged by our MSK EMSY software. MSK systems offer an advantage over other suppliers in that both the robot cell with individual end-of-arm tools and peripheral devices such as the application of bottom/intermediate layers, conveying technology, and the packaging system are designed, produced, assembled, and delivered from a single source. The feeding of individual packages to the palletizing station is also part of the MSK portfolio. Because MSK designs and manufactures all components itself, the systems are individually configurable based on the MSK modular principle yet still standardized.

Sustainable load securing – savings in pallet packaging

MSK packaging machines secure your products on pallets and are suitable for use with recycled or biodegradable films. Special MSK technology not only saves packaging material but also increases load stability. Closed hoods also offer the advantage of theft protection. Thanks to continuous innovation and patented processes, MSK's packaging systems enable constant savings in energy and film consumption.

MSK conveyor systems

The automation of your logistics could start with fully automated truck unloading. This means that the delivered pallets can be fed into the internal logistics system via an automatic system as soon as the goods are received. Automatic truck loading is also possible. Furthermore, MSK offers not only stationary conveyors (Transtech) for transportation, but also mobile transfer cars (MSK Linktech) and driverless transport systems (AGVs). In this way, unrest caused by forklift traffic can be avoided. Experienced project engineers develop customized layout concepts for this. Feel free to contact us at LogiMAT 2026.

Complete solutions for your pallet logistics

MSK advises and optimizes you in the automation of your intralogistics processes regarding the entire pallet logistics. You benefit from standardized overall system control. Networked communication and the transfer of parameters ensure simple operation without interface problems. Another advantage is the homogeneous and unconditional documentation, software and spare parts structure as well as a central service interface for the entire system.

Experienced project engineers will develop a tailor-made concept for you.

From a single source – we mean what we say.

MSK plans, designs, manufactures, programs, tests, and commissions your entire system in-house, both before delivery and on site. All key components are perfectly coordinated and delivered as one integrated solution, including:

- Robot palletizing cells with customized end-of-arm tools

- Layer handling and conveying technology

- Stretch and shrink packaging systems

- Uniform control, documentation, and data management across the entire line

Our modular systems are individually configurable yet standardized and fully integrated. All parameters are entered once and shared seamlessly across the entire line via the MSK EMSY HMI. After delivery, our customer service team supports you quickly and reliably with maintenance and spare parts services — providing the long-term investment security you need.