Bottle conveyor technology for the glass industry

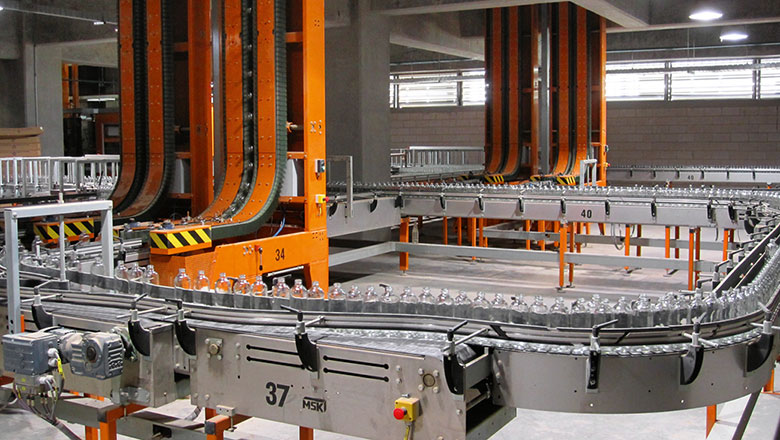

MSK Bottle conveyor systems for the hollow glass industry

Fully automatic bottle transportation for complex bottle conveyor lines at the Cold End

Decades of experience with the Cold End have made MSK one of the leading suppliers for conveyor systems in glass factories. MSK provides the complete intra-logistics at the Cold End, including bottle conveyor systems, from the lehrs to the palletizing system - all from a single source.

Standardized connection to inspection machines

MSK bottle conveying lines include standardized interfacing with all major inspection machine types.

Highly flexible bottle conveyors

The modular design of the MSK Bottle conveyor systems with adjustable rail guides provides a high degree of flexibility, layer pre-forming and thus a fully automated process for your bottle transport. Attention to technical details, high-quality materials, variable dimensions and solid workmanship in accordance with TQM-standards make your system reliable.

Advantages:

- Stainless steel and premium components for long life

- Intelligent control and process data control with MSK EMSY software

- High flexibility of the bottle conveyor lines & sorting lines with expansion options thanks to the modular system

Additional modules for MSK Bottle conveyor systems

Selected supplementary modules fit MSK bottle conveyor lines addapted to the individual requirements of a Cold End.

MSK accumulation table - Layer table for hollow glass and bottle layers.

The accumulation table accumulates the glass containers to a layer. The layer of bottles are raised by the gripper head and put in to the palletizing system.

Advantages:

- Plastic mattop chains for a smooth bottle transport

- Low wear

- Continuous adjustment to different layer pattern

- Optional: Accumulation table for either one, two or three layers of bottles are available

- Optional: Film strapping system MSK Looptech, for safe internal bottle transportation

Hygienic transport of your products

To ensure hygienic conveying of the bottles, MSK optionally offers metal covering for your products. All drives use food grade oil.

Vertical side grip conveyors

For space saving or special logistical requirements, MSK offers bottle conveyors with side grip technology such as vertical conveyors, omage conveyors, bottle bridges and bottle elevators. The vertical side grip conveyors can be equipped with bottle blowout and vibration facilities.

Omega conveyor

MSK omega conveyors are used for passages as well as for turning and cleaning the bottles with an air blow.

Continuous Motion Divider

The Continuous Motion Divider distributes the glass containers to four or more lines without pressure. No empty spaces occur between the individual glass containers.

Equipped to meet future requirements

MSK bottle conveyors are designed to accomodate tomorrow's requirements and can be expanded easily. A particular advantage is the equipping of the sides with fixtures for sensors, marking systems and other accessories as a standard feature. Additional components can therefore be fitted quickly and without complications during active operation.

MSK Bottle alignment station

The increase in the number of special forms in the glass and bottle production presents the glass industry with new challenges. A high level of flexibility of the Cold End with low space requirements is called for.

MSK has developed a bottle alignment station, which is characterized by an extremely compact size. Central feature: The MSK Bottle alignment station is located "mobil" on a movable rack. It can be docked on the side of a bottle line without the line having to be mechanically disassembled.

- Space-saving compact design

- Temporary installation is possible

- Mobile use on different lines

- Cost savings through flexibility: Lines that do not require a permanent bottle alignment station will not be burdened by a machine purchase.