Shrink wrapping for glass

Pallet shrink packaging systems - Efficient packaging solutions for the glass industry

The quality requirements for beverage and food packaging are steadily increasing. This also applies to the manufacturer of bottles and glasses.

MSK shrink packaging machines offers the glass industry a cost-effective range of packaging solutions - with very good product security against damage or contamination and in compliance with the quality requirements DIN ISO 9000.

MSK pallet shrink wrap machines and procedures for the packaging systems of glass lines consider crucial criteria:

- High load safety during product transport

- Protection against moisture and dirt

- Easy maintenance for minimum down times

- Reduced energy consumption - up to 40% less gas consumption

- Reduced material costs - film saving in spite of a high standard of safety

Shrink wrap machine MSK Paratech

The hood applicator with the parachute principle

The unique MSK Paratech is to date the most sold shrink hood applicator. The secret of its success lies in the simplicity and the exceptional ease of maintenance of the machine.

Advantages:

- Easy maintenance due to ground level, easily accessible film feed keeps downtime reduced to a minimum

- Film is opened up by natural air jam from the parachute movement: Complete and reliable opening of the film

- Optional: Version with maintenance-free time belts

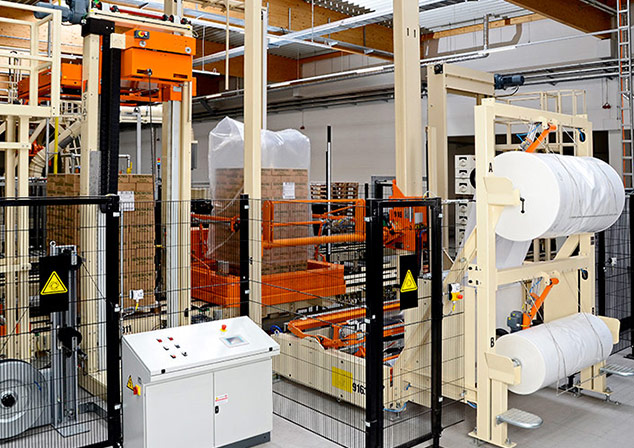

Shrink wrap machine MSK Multitech

The packaging solution with the highest level of flexibility

If equipment is flexible and space-saving, easily adaptable to varying products and processes, the existing production area can be used far more efficiently. The machine has a compact design, it can process up to four film formats or thicknesses fully automatically and run any opening dimensions flexibly.

The tried and tested MSK shrink wrap system grants a perfect pass fit as well as a non-contact application of the film hood, which facilitates the use of thinnest films. The machine head can be lowered to working level thus enabling easy and fast maintenance without a lifting platform or ladders.

Advantages:

- Compact design - Less space required

- Use of the thinnest films due to no-contact application

- Simple maintenance thanks to lowerable machine head and maintenance-free time belt technology

- Very low energy consumption

Lowerable machine head (EP 2 336 034) for easy maintenance and replacement of the welding bar

The machine head of the MSK Multitech can be lowered to operator level. Floor-level access without platforms or ladders on MSK packaging systems offers a high level of operator and maintenance friendliness. This makes equipment maintenance simpler and faster.

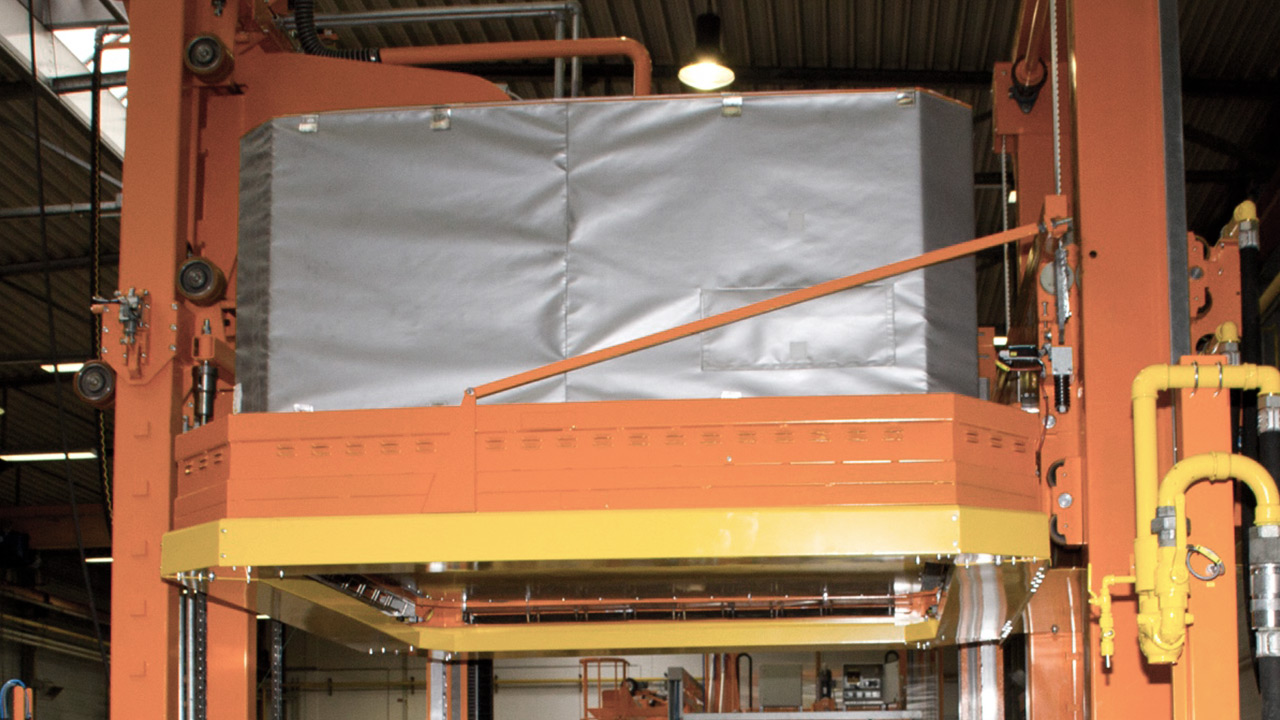

Pallet shrink wrapping with hot air

MSK shrink packaging systems are characterized in particular by the gentle warmth dosing of the MSK shrink frame: They ensure the preservation of the elasticity and the fatigue strength of the film during long storage periods.

Advantages:

- MSK shrink frames are particularly operationally secure and they require very little maintenance

- Suitable for the use of thin films

- Reliable welding of bottom film or product covering film

- Modern and certified safety system (DVGW certified) with air and gas pressure monitoring

- Maintenance-free MSK heating elements with 5 years warranty

Safe and sustainable MSK shrink frames

Efficient MSK technology

A special MSK mixed air system heats the film precisely and gently. This preserved the film's elasticity and fatigue resistance. MSK heat recycling thereby ensures optimal energy efficiency. We offer 5 years of warranty for our maintenance free MSK heating elements.

Combination of the collar shrink process and bottom sheet for a six-sided protection

The combination of the collar shrink process and bottom sheet provides six-sided protection of the pallet load. The ingress of dust and dirt can thus be prevented. An MSK pallet dressing line provides the empty pallets with the bottom film sheet before the glass containers are palletized.

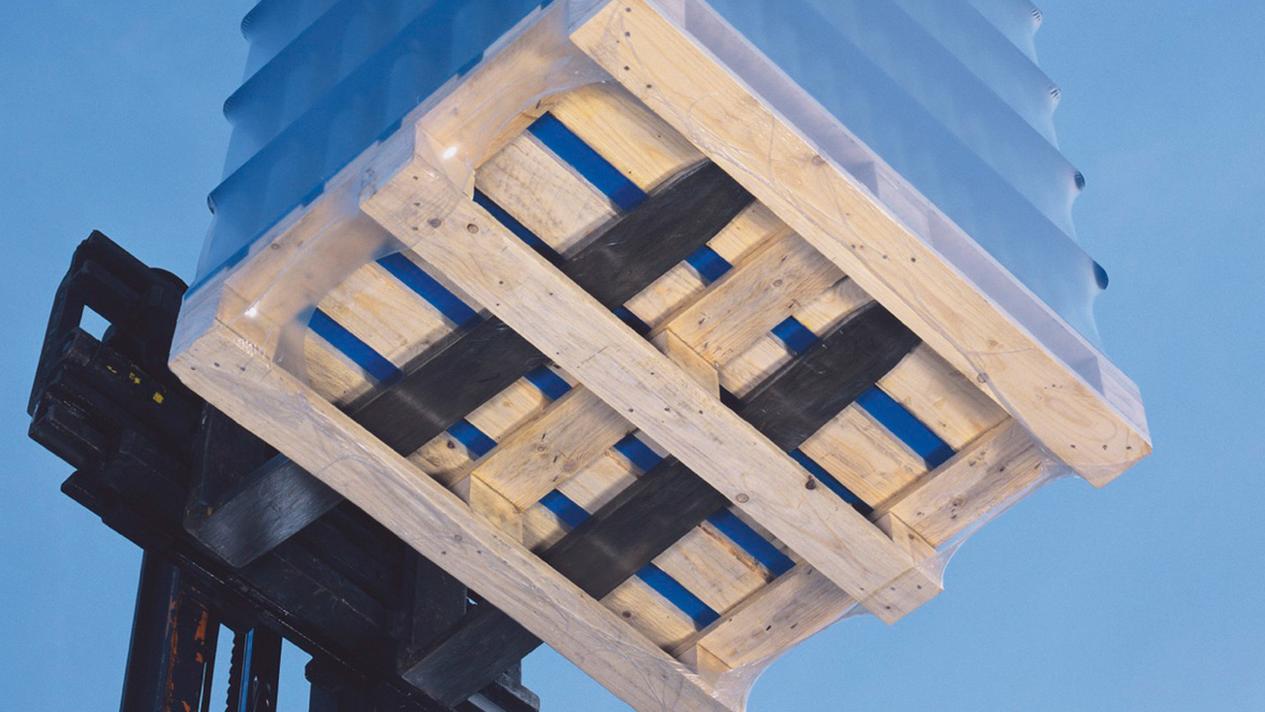

Film-free pallet feet with MSK Formtech

Developed and patented by MSK, the MSK Formtech (EP 3 147 226) provides film forming between the pallet blocks, which allows for the automated pallet handling in high-bay storage systems. AGV's and automated truck loading systems.

MSK Undershrink-system

Hardly any procedure has influenced pallet shrink packaging as much as the MSK Undershrink system. This MSK principle which was patented in the eighties has lead to a significant reduction of the film thickness in the packaging of glass.

In conjunction with the MSK Anti-collage-procedure the undershrink system enables acrease-free shrinkage of the packaging film. The MSK Undershrink system adjusts itself automatically to the pallet contour during pallet packaging to ensure a safe release of the pallet. Deep under the pallet runner, the shrink-wrap develops its maximum strength, thus offering an optimal load stability.