Stretch hood packaging for logistics centers

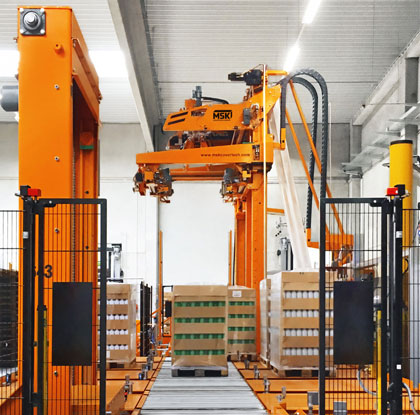

MSK stretch hood packaging systems for logistics centers

MSK stretch hood pallet packaging for mixed goods pallets

Transport packaging for picked goods needs to adapt flexibly to the characteristics of the load. Stretch hood packaging with thinnest films down to 20 µm is often a viable alternative to stretch wrapping and offers significant additional advantages. Hood stretch pallet packaging offers important additional benefits such as theft-proof pallet packaging, minimized film roll replacement and reliably calculable film consumption.

ADVANTAGES:

- Increased theft protection thanks to closed hood

- Significant reduction in film roll replacement

- Calculable film consumption

- Easily legible barcodes and logos under the transparent film

- Easy maintenance with lowering machine head and low-maintenance timing belt technology

Efficient MSK Tensiontech stretch hood machine: Precise stretch technology using exact contour detection

A special MSK technology used by the Tensiontech stretch hood machine, which carefully stretches the film around the loads, has already been adopted by several logistics centers and allowed them to switch their packaging method from stretch wrapping to efficient stretch hood technology. The MSK stretch hood machine first records the precise load geometry to produce perfectly-fitting film hoods using a minimal amount of film. The stretch hood machine’s PLC control system automatically computes the correct hood length, tension force and stretching dimensions of the film as well as the kind of hooding operation. The system adapts the tension of the film and the hooding process accordingly, saving film and ensuring high load stability.

Closed film hoods for increased theft protection

Compared to stretch wrapping, a closed film hood offers improved protection against theft. The products are also protected on 5 sides against dirt and moisture during loading and transport. Barcodes and logos are easy to read under the transparent film hood, since only one layer of film is applied around the load in contrast to stretch wrapping.

Automatic pallet handling with open pallet feet

For automatic pallet handling using AGV as well as in high-bay warehouses, MSK offers film hood packaging which keeps the pallet feet film-free. To accomplish this, Tensiontech stretch hood machines are equipped with the MSK collar stretch procedure, for which the film is placed on the top board of the pallet.

Easy operation with savings in maintenance and film

MSK stretch hood packaging machines are specially designed to be extremely low-maintenance and easy to operate for use in logistic centers. All movements are powered by electric motors using low-maintenance timing belts; the use of hydraulic systems is avoided completely. The machine head can be lowered electrically for maintenance and the sealing bars are easy to replace using quick-change systems. The EMSY visualization system allows for operation primarily based on 3D images, often without intensive training and instruction. Integrated maintenance management facilitates the planning and achieving of your targets during peak handling times. Independently of the operator, MSK stretch hood machines ensure permanently low film consumption, optimum pallet load security and contribute to the sustainability of logistics processes, regardless of the operator.

Stretch Hood high-performance systems that occupy minimal space

MSK stretch hood systems operate in confined spaces. Thanks to their compact design, the machines have low space requirements, comparable to those of a stretch winding machine. A special MSK method for prefabricating the film hood while a pallet is being scanned guarantees a rapid packaging cycle for the picked pallets.

Tensiontech stretch hood machines also feature a machine head that can be lowered down to working level, considerably simplifying the required maintenance tasks and minimizing maintenance times. Another advantage is that the film rolls are replaced outside the protective guards, so roll changes can be carried out without a standstill of the system.

Around-the-clock technical support

Particularly during seasons with a high throughput, significant time pressure and additional non-technical support staff, on-site technical support available around-the-clock is crucial. MSK offers a 24-hour on-call service even around Christmas. With its international presence and multilingual service staff, MSK is a reliable partner for this requirement.