Transparency for the glass industry – MSK EMSY analytics

Data networking at the Cold End with MSK EMSY analytics

Transparency and raising efficiency due to analysis of the system as a whole

With MSK EMSY analytics you can achieve a completely new level of transparency in the efficiency of your Cold End. The web-based application connects in the sense of Industry 4.0 the data of all machines controlled with EMSY at the Cold End, allowing centralized analysis of the entire Cold End, based on real-time data. MSK EMSY analytics provides transparency for the overall efficiency of a Cold End, and identifies options for increasing efficiency.

ADVANTAGES:

- Centralized Cold-End process planning using real-time data

- Analysis of the entire system based on networked statistics

- Automated backups for high data security

- Increasing efficiency in the short and long term

- Maintenance and job-change management

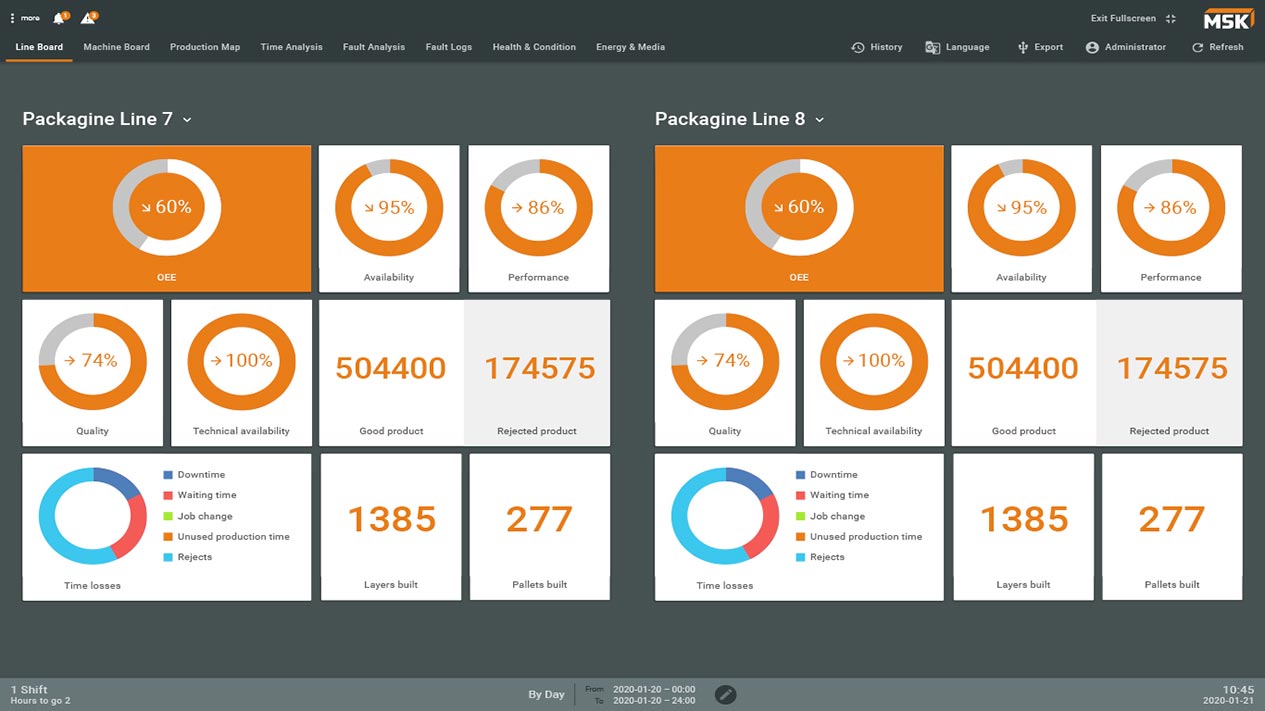

Status information at a glance in real time

With the personalized dashboard, your individual preferences for status information of each system or component can be displayed at a glance in real time. Health & condition monitoring, energy consumption and performance data of individual components are shown in a graphic display. The derived recommendations for action serve to increase the efficiency of the Cold End in the short and long term.

FUNCTIONS:

- Web-based application access

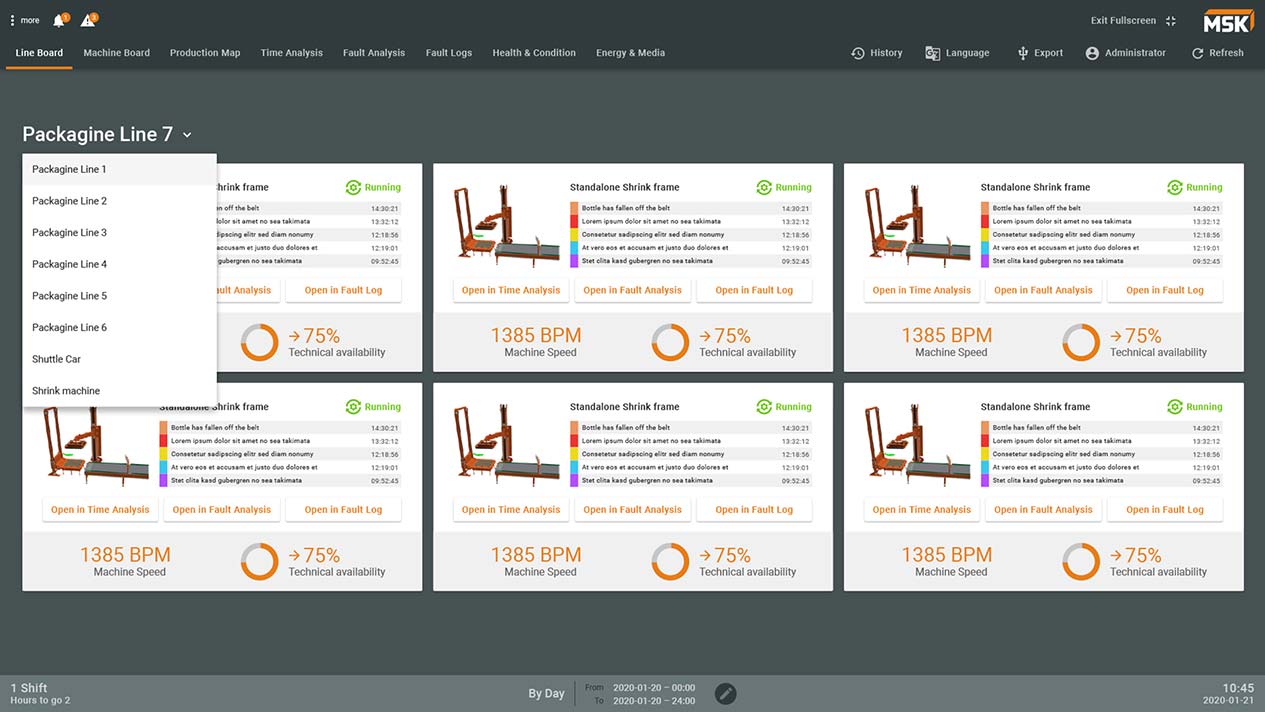

- Dashboard display for all production lines connected

- Detailed analysis of the networked machine areas

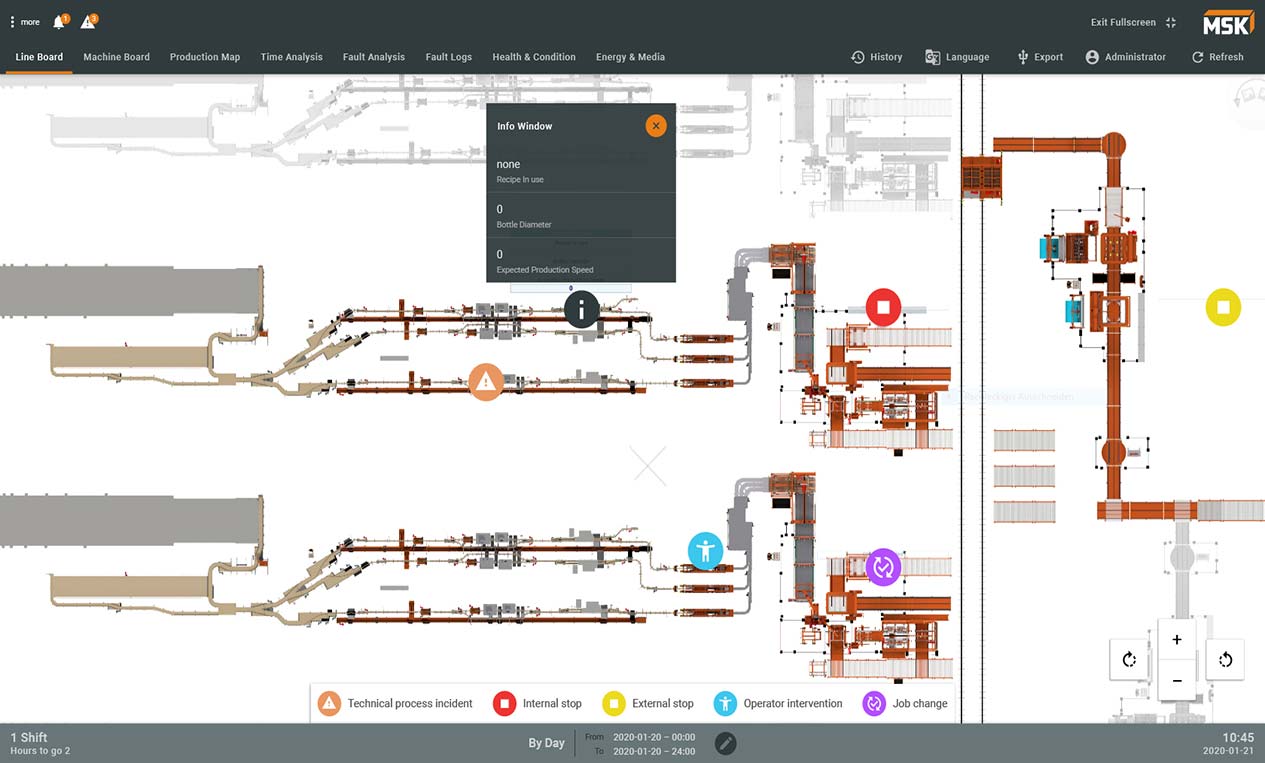

- Overall layout view with machine status, pallet information tracking, etc.

- Centralized analysis and statistics

- Centralized fault logs

- User-defined settings

- Remote support