Complete systems for the glass industry

MSK Complete systems for the hollow glass industry

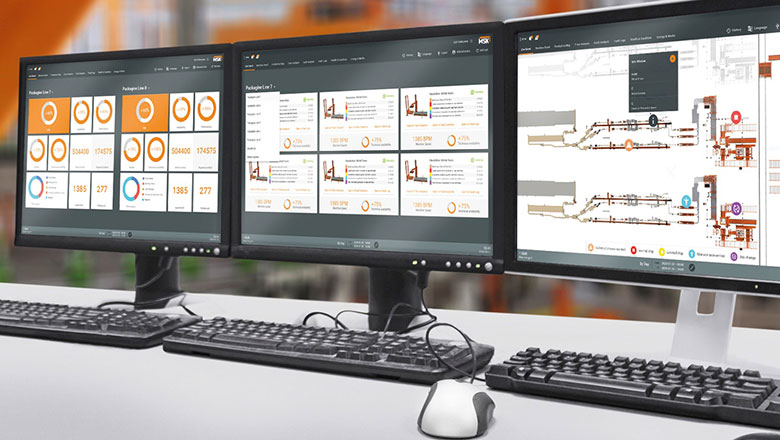

NEW: Data networking at your Cold End with MSK EMSY analytics

With MSK EMSY analytics you can achieve a completely new level of transparency in the efficiency of your Cold End. The new software connects the data of all machines controlled with EMSY at the Cold End along the lines of Industry 4.0, allowing centralized control of the entire Cold End based on real-time data. MSK EMSY analytics provides transparency in the overall efficiency of a Cold End and identifies options for increasing efficiency.

Advantages:

- Centralized Cold End process planning using real-time data

- Analysis of the entire system based on networked statistics

- Automated backups for high data security

- Increased efficiency

- Maintenance and job-change management

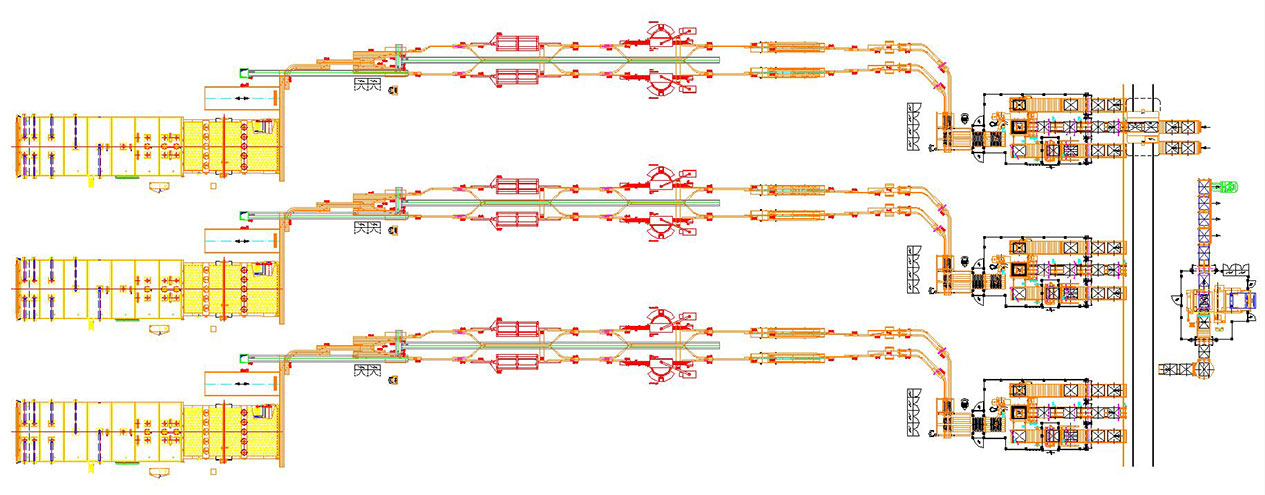

The entire Cold End of the glass production process from a single source

MSK provides a full-service and is one of the market leaders for the entire Cold End of a glass production. After the lehrs MSK provides all of the necessary processing equipment from a single source. All modules are optimally coordinated with each other and can be controlled simply and in coordination with each other using the visualization software MSK EMSY 6. The advantages for our customers: Numerous component interfaces, which are usually a potential sources of error, are eliminated, the plant efficiency increases.

MSK Systems for the Cold End:

- Bottle separation after the lehr

- Bottle conveyor systems

- Bottle orientation

- Layer formation (stacker, layer strapping)

- Palletizing systems

- Pallet packaging machines

- Pallet conveyor systems

- Software systems for overall plant efficiency, machine control and visualization

- Numerous additional modules

Savings through standardized and networked machine control

Using the MSK EMSY software for the control of the entire Cold End will result in significant savings benefits, as it will make the material flow on the entire Cold End clearly control and configurable. Once entered parameters can automatically be transferred to other machines.

Advantages:

- Automatic transfer of the parameters in the PLC control without repeated data entry

- Standardized machine operation means less effort involved in training

- Continuous tracking of the entire logistics process up to the pallet storage

- Automated machine settings reduce consumption

- Support for maintenance, spare parts requirements, and troubleshooting

Customer-specific engineering

With over 40 years of experience at the Cold End in the glass industry a team of specialists designed customized total solutions from planning to production of a system according to customer specific requirements. Thanks to the MSK modular principle of palletizing systems, packaging systems and the matching pallet conveyor technology a MSK system is also equipped for future requirements and offers a high degree of flexibility when expanding or modifying the Cold End.

A flexibility enhanced by MSK software range (EMSY 6, EMSY analytics, EMSY move and EMSY smart)