MSK at Interpack 2023

Would you like to automate your production flow and reduce packaging costs? The topic of sustainability is becoming increasingly important. Our MSK specialists will advise you on sustainable solutions at Interpack 2023. You will find us in hall 12, booth C52. Arrange a meeting at sales@msk.de. We look forward to meeting you!

Resource-saving and sustainable secondary packaging

With the new shrink frame generation, we minimize your energy consumption sustainably. The newly developed technology reduces gas consumption by 13%. An additional saving of 40% is possible with the MSK Covershrink energy-saving module. The MSK Corritech electric shrink frame with eCovershrink, on the other hand, operates entirely without gas. By completely dispensing with fossil fuels, we thus support you on the path to climate neutrality without you having to forego the stability of shrink packaging. MSK shrink packaging systems are also in demand on the market because they are suitable for use with recyclable or biodegradable films. The shrink film used is also fully recyclable.

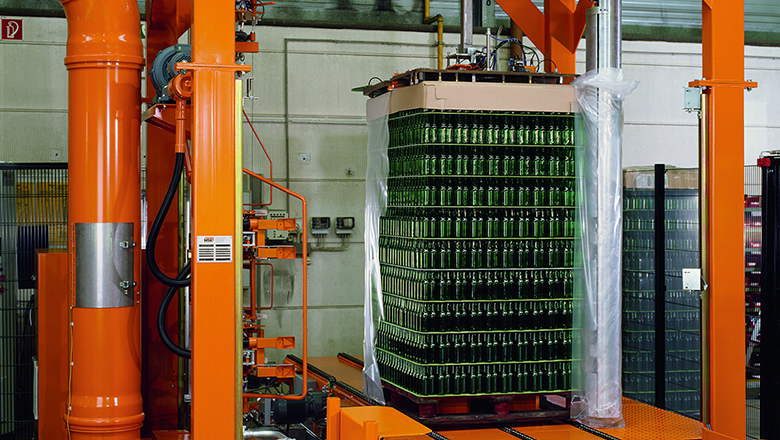

Flexible MSK stretch hood packaging – film packaging according to your needs

The fully automatic stretch hood machine MSK Tensiontech works with a special film stretching process when assembling and attaching a stretch hood. This enables the packaging of a wide variety of palletized or non-palletized load units with a flexible stretch hood. The MSK system stretches the film hood specifically for each package in any coordinates in the longitudinal and transverse direction - and thus offers exactly the flexibility you need.

Resource-saving technology is also used by MSK in its stretch hood systems. Thanks to the compact design, balanced vertical movements and a patented stretching process, you achieve very low energy consumption of less than 0.07 kWh per pallet and can process the thinnest films down to 20μm. Here, too, the use of films containing recycled material is possible.

Would you like a detailed consultation? We are happy to help.

Unwrapping made easy – MSK Defotech makes it possible

In order to automate the pallet logistics not only at the end of the production line, but also in the incoming goods department, MSK offers a complete package for unpacking pallets from film and strapping, as well as subsequent depalletizing from a single source. The MSK portfolio in this area includes the fully automatic MSK Defotech unwrapping system, a fully automatic destrapper MSK Destraptech, as well as portal or robot-based depalletizing systems. The MSK Defotech unwrapper is available for all standard packaging films. After the pallets have been unpacked, the MSK Defotech automatically prepares the recycling of the film using a special film removal system. If the packaging films are collected by type, they can be completely recycled.

Your fully automatic pallet logistic - from a single source

MSK also advises and optimizes you on the partial automation of your intralogistics processes or pallet handling. Whether from goods receipt, within production or in the area of pallet packaging and in the direction of goods issue, there are often untapped potentials for cost reduction: minimizing forklift traffic, reducing manual pallet handling or optimizing loading processes.

Another advantage - the continuous monitoring of energy and film requirements based on live key figures and statistics in real time is possible through the use of digital products such as the MSK EMSY software. The software also networks the controls of individual machines into a complete digital system and makes a significant contribution to increasing the efficiency of the entire packaging line.

Experienced project engineers will be happy to develop your tailor-made concept.

MSK - Partner of the industry for palletizing, conveying, packaging and unpacking systems

For almost 50 years, the MSK Covertech Group has been one of the leading manufacturers of palletizing, conveying, packaging and unpacking machines for the automation of the entire pallet handling with more than 6,200 systems sold, around 600 employees and locations in Germany, France, Hungary, USA and China from goods receipt to truck loading or to the finished goods warehouse. Prominent manufacturers from a wide variety of industries belong to MSK’s regular customer base. MSK develops and produces conveyor technology and packaging systems with a high level of vertical integration itself and also controls its systems with its own software.

04 – 10 may 2023

Düsseldorf, Germany

Hall 12, booth C52