Shrink Wrap Systems

MSK Shrink wrap machines - Efficient packaging solutions for pallets and large containers

Prepared for the future: Unique and cost-effective MSK shrink packaging systems

MSK industrial shrink wrapping machines and shrink hood applicators offer pallet packaging solutions that look to the future. Our future-oriented pallet packaging systems were developed in close cooperation with leading companies from a wide variety of industries. In addition to high flexibility of pallet formats and maximum load stability, they offer significant savings advantages in terms of energy, material and maintenance.

Hood Shrink Wrap Machine MSK Paratech

The hood applicator following the parachute principle

Advantages:

- Easy to maintain due to easily accessible film feed at ground level

- Downtime reduced to a minimum

- Reliable opening of the film hood due to natural air accumulation from the parachute movement

- Maintenance-free time belt technology

The MSK Paratech shrink hood machine is characterized by its simplicity and ease of maintenance. The industrial shrink wrap machine pulls film hoods over the pallet loads following the so-called parachute principle.

Hood Shrink Wrap Machine MSK Multitech

Maximum flexibility in the hood cover

Advantages:

- Compact design - Small footprint

- Use of the thinnest films with contactless hooding

- Easy maintenance due to lowerable machine head

- Maintenance-free time belt technology

- Very low energy consumption

The pallet shrink wrap machine MSK Multitech is a hood applicator that flexibly adjusts to changing products and processes. With its compact design, the packaging system processes up to four film formats or thicknesses entirely automatically. The flexibility of this Covertech solution means that it will adapt to any opening dimensions.

The machine head of the MSK Multitech can be lowered to working level. Maintenance can be carried out very easily and without ladders or a platform.

Shrink Film Sleeving Machine MSK Flowtech

Cost-effective industrial packaging for specific pallet formats

Advantages:

- Especially suitable for packaging different product formats (length, width)

- Save materials through the use of thinner films and film sleeves tailored to each individual package

- Easy film handling

- High packaging performance

The MSK Flowtech shrink film sleeving machine was specially developed for cost-efficient pallet packaging of any number of very different pallet or product formats.

MSK Safety Shrink Frame

Gentle pallet shrink wrapping using hot air

MSK pallet shrink wrap machines are characterized by the gentle application of controlled amounts of heat using MSK shrink frames: They ensure the film retains its elasticity and fatigue strength during prolonged storage.

The product-specific combination of hood applicator or film sleeving machine with an MSK shrink frame system forms an optimal and cost-efficient packaging system for pallet packaging.

Advantages:

- Energy-efficient low-temperature mixed air system

- Particularly reliable and very low maintenance

- Suitable for the use of thin films

- Automatically adjusted hot air flow for shrinking to specific pallet dimensions

- Modern and tested safety system (DVGW-certified) with air and gas pressure monitoring

- Maintenance-free MSK heating elements with 5 years warranty

Shrink-wrapping with electric heating system

The MSK Corritech electric shrink frame model works completely without the use of gas, helping companies on their way to climate neutrality. This allows highly stable shrink wrapping to be realized while sustainably waiving fossil fuels – without compromises.

Additional modules for shrink wrapping systems - developed for special requirements

MSK Undershrink Process

During pallet shrinking, the MSK Undershrink system secures the packaging film further underneath the pallet runners. This gives the shrink film its maximum hold, thereby providing maximum load stability for the packages on the pallet.

Advantages:

- Reduction of the film thickness in pallet packaging

- Maximum load stability

MSK Covershrink: For shrink frame systems with energy savings of up to 40%

MSK shrink frames can be equipped or retrofitted with the patented MSK Covershrink. Depending on the film thickness and pallet size, this can save up to 40% of the energy required for heating during pallet shrinking.

Advantages:

- Energy savings up to 40% when shrinking pallets

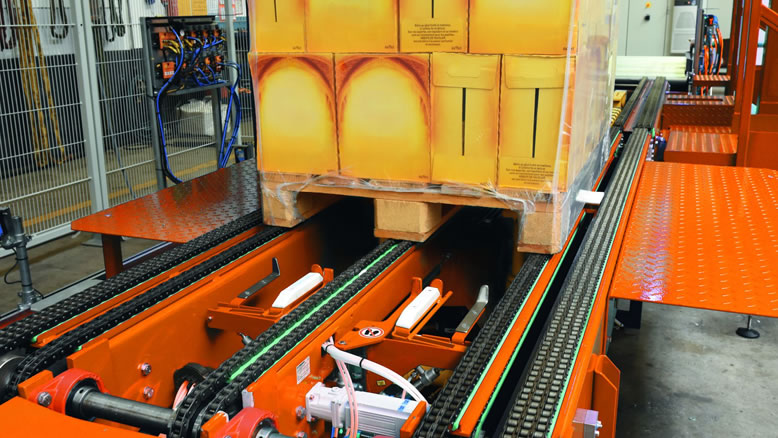

Film Hood Packaging with open pallet feet - for automatic pallet handling systems

MSK shrink hood applicators can be equipped with the new MSK film forming device to keep the pallet feet free of film. Special shaping of the film during the shrinking process leaves the necessary space between the pallet runners which is required for automatic pallet handling systems.

Advantages:

- Transportation with AGV systems

- Handling in automated high-rack storage systems

- Automatic truck loading