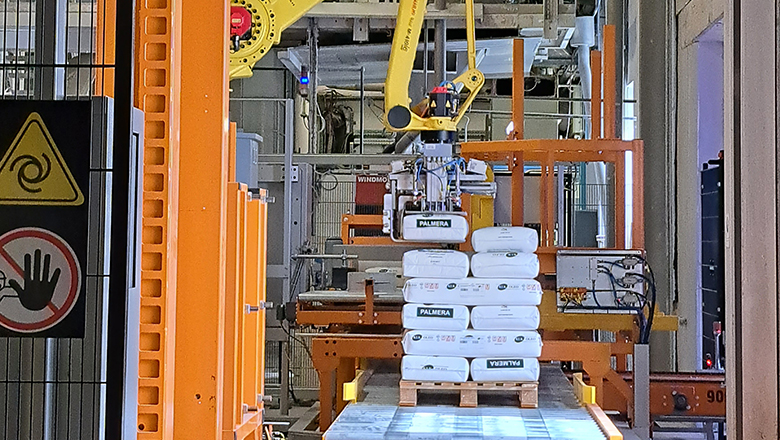

Palletizing systems for building materials & chemicals

MSK Palettizing systems for the building materials and the chemical industries

Efficient palletizing and depalletizing of bagged goods, canisters, drums, cases, cartons and much more

MSK palletizing systems palletize a wide variety of building materials and chemical products in all desired layer patterns and depalletize them in the incoming goods area in the tightest of spaces. Whether as a robot palletizer or as a conventional palletizing system - thanks to the modular design, all MSK palletizers can be equipped with different palletizing heads and modules. In this way, they offer the greatest possible flexibility and high efficiency in process automation.

ADVANTAGES:

- Fully automatic palletizing and depalletizing in the tightest of spaces

- Great flexibility with high precision

- Suitable for different packages and layer patterns

- Modular design and additional modules

- Easy maintenance and low wear

Customized robotic palletizing systems for a wide range of packaged goods

MSK robotic palletizing systems are designed according to individual requirements and palletize even large-format or heavy products such as drums, canisters, cases and other packaged goods with high performance. Equipped with different palletizing heads and additional modules, MSK robot technology is an efficient and powerful palletizing system. Customer-specific layout solutions with integrated conveyor systems, packaging systems and peripheral devices enable customized automation of the entire intralogistics when it comes to pallet handling.

Modular bag palletizers with high flexibility

MSK bag palletizers for the building materials and the chemical industries are designed according to a modular principle. The palletizing head picks up the bags gently and safely from the conveyor belt. The bags are stacked on the carrier pallet according to various packing patterns. For changing products, a job change is possible quickly and easily by adapting or changing the palletizing head. The MSK EMSY visualization software provides the best possible support with graphic-supported instructions and all the necessary product parameters.

Multifunctional robot palletizer MSK Robotech works in the tightest of spaces

In addition to the precise stacking of products on a carrier pallet, the MSK Robotech robot palletizer can also perform other tasks if required. As part of the quality check, it ejects products from the palletizing process if defects are detected by depositing them on a separate place. The palletizing robot is also able to place bottom cartons or intermediate trays from an MSK tray magazine flexibly and with high performance. This turns the palletizing station into a multifunctional system in a very confined space.

What requirements do you have?

We are curious to see what palletizing or depalletizing requirements your product will present to us. Contact us! We will be pleased to advise you.

Palletizing and load securing in harmony

If the palletizing of packages and the packing of pallet loads come from a single source, savings can be achieved. A standardized control concept for the entire line, interfaces in communication and the transfer of parameters ensure simple operation without interface problems. Special requirements for securing loads can already be taken into account when designing the palletizing system.