Complete Systems for Building and Chemical Materials

MSK Full Service Systems for the Building Materials & Chemical Industry

Automating the entire pallet logistics including palletizing, transporting and packaging from a single source

In an effort to automate the entire material flow and pallet handling from incoming goods up to truck loading and reducing the use of forklifts, MSK creates customized and fully automated full service systems with pallet conveyor technology, palletizing systems and pallet wrapping lines with hood stretching or shrinking technology. For products with special requirements, we develop individual solutions with sophisticated pallet conveyor technology. The full service system is controlled according to individual requirements by the MSK EMSY software, featuring communication interfaces for the internal ERP-system and peripheral devices.

Advantages:

- Automated pallet logistics without, or significantly reduced forklift traffic between the incoming goods area, production area, warehouse or high-bay storage area

- Information networking with MSK EMSY control

- Communication via ERP-system and peripheral devices for high-level process automation

- Efficient palletizing and packaging lines with stretch hood and shrink wrapping technology from a single source

- Fully automated truck-loading and off-loading process

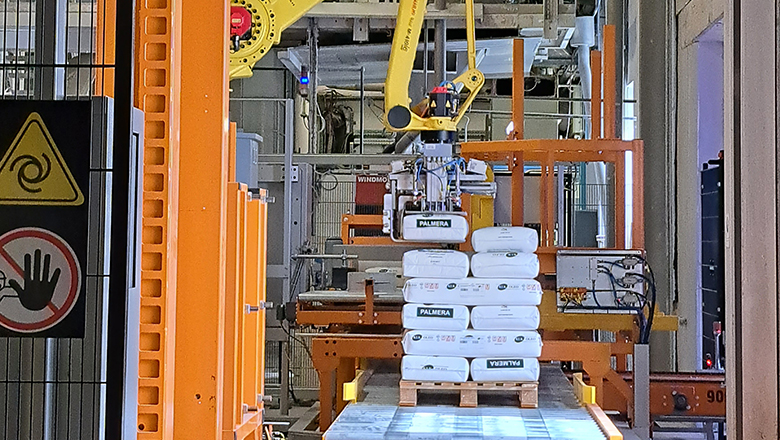

Flexible and efficient palletizing systems with robot technology

MSK robotic palletizing systems palletize a wide variety of products from the chemical and building materials industries in all desired layer patterns - and in the tightest of spaces. Thanks to their modular design, MSK palletizers can be equipped with different palletizing heads and additional modules. In this way, they become a highly efficient palletizing station with the greatest possible flexibility.

Networked and Intelligent Logistics Process with MSK EMSY

The required processes can be implemented in a custom-tailored manner as well as easily comprehended and visualized by the operator with the MSK EMSY 6.0 control and visualization software.

The database-based system provides communication interfaces to your ERP-systems as well as peripheral devices, such as scanners, scales or labeling equipment. MSK EMSY receives the commands for the destination of a pallet through the network and reports positions and data of a pallet back to the ERP-system. All pallet data is carried forward throughout the entire logistics process without loopholes. Delivery notes for outbound goods, for example, can also be generated automatically through this network.

Automatic Truck Loading

Increased loading efficiency: the MSK pallet pre-sorting function enables fully automated, systematic truck loading without the use of a forklift.

Special Palletizing and Packaging Equipment for Chemical Production Facilities

MSK offers machine models specifically designed for the chemical industry, using stainless steel and plastic coatings for certain equipment components. This enables the long-term use in a chemical facility environment.

Customized Engineering

Based on decades of experience in the building materials and chemical industry, MSK specialists design customized full service solutions according to customer-specific requirements with MSK systems, such as

- Pallet conveyor systems

- Stationary conveyor systems (roller conveyors, chain conveyors, plate conveyors, shifting conveyors, rotating elements)

- Mobile conveyor systems (shuttle cars, vertical conveyors, AGV-transport systems)

- Palletizing systems

- Palletizing robots

- Pallet packaging systems

- Stretch hood systems

- Shrink wrap systems

- Hybrid systems (shrinking and stretching in one system)

- Energy saving module MSK Shrinkcover

- Software systems for controlling and visualizing the entire system

- Numerous ad-on modules

- Scale

- Scanner

- Pallet centering

- Labeling device

- and much more