Pallet shrink wrap for chemical products

MSK shrink packaging systems for the chemical industry

Chemical products place very high product related demands on load stability, especially when stacking containers in pillars on pallets. Pallet shrink packaging offers the highest load stability with negligible pressure on the product.

MSK Pallet shrink wrap machines - Packaging systems for requirements of chemical production plants

Specifically designed for production plants in the chemical industry offers MSK optional machine designs. This version offers stainless steel and/or plastic coatings for selected machine or conveyor components including special, protected electrical components.

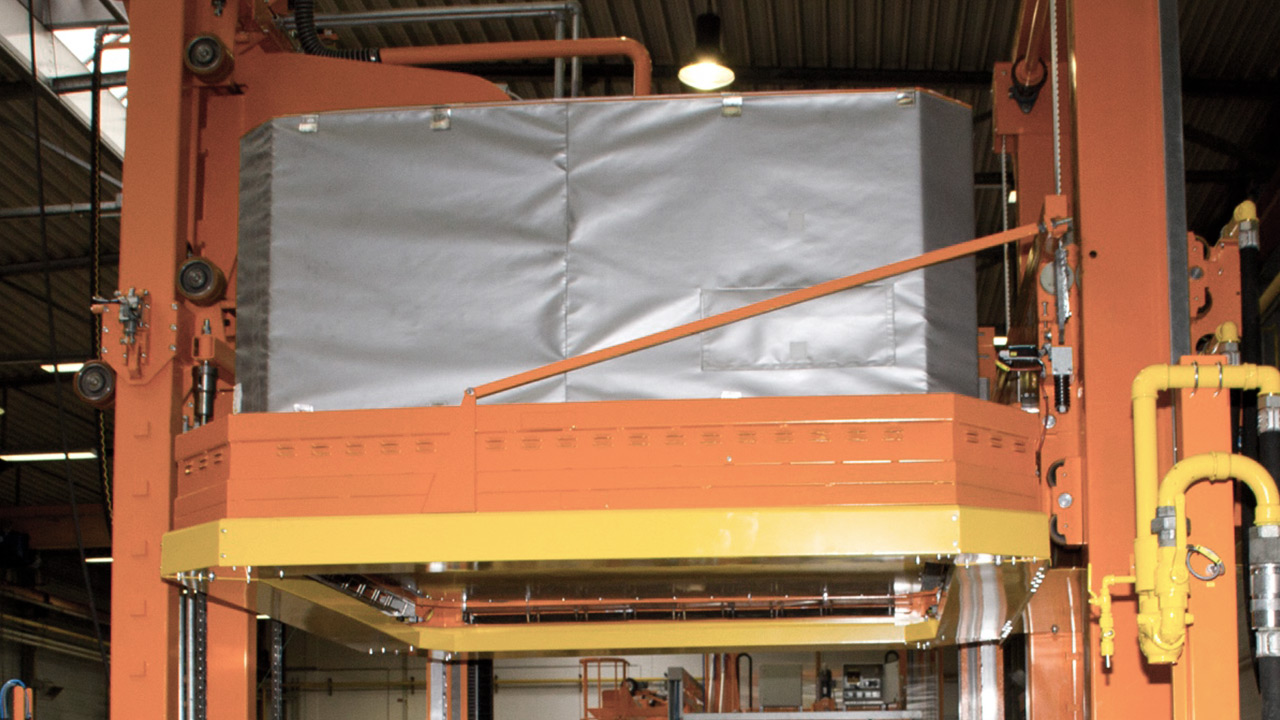

MSK Multitech pallet shrink wrap machine:

Space-saving packaging system for changing product formats

The shrink packaging system MSK Multitech owes its name to its versatility. The machine automatically processes up to 4 film formats and offers two processes in one machine: hooding and shrinking. This means a high level of flexibility in the smallest space.

Thanks to the high-quality MSK seam weld the system can fashion permanently reliable film hoods.

MSK pallet shrink packaging machines work with a mixed air heating process at low temperatures. Thanks to the gentle shrinking process the fatigue strength of the film is not weakened. The product can be stored outdoors for long periods of time.

Advantages:

- Avoidance of deformation of pressure-sensitive products

- High load stability even if not palletized flush with the pallet

- Reliable film hoods by high-quality seam welds when tailoring the film hood.

- Security shrink system with low temperatures

- The machine head can be lowered to ground level, which notably simplifies maintenance. Maintenance-free time belt technology

- Maintenance-free MSK heating elements with a 5 year warranty

MSK Undershrink procedure for high load stability

Already patented in the 1980s; the MSK undershrink procedure has revolutionized the pallet shrink packaging process, the main reason being that it has enabled a considerable reduction in the film thickness for the pallet packaging.

The MSK Undershrink system automatically adapts itself to the pallet contour thereby creating safety and stability for the palette. Deep under the runners of the pallet the shrink-wrap develops its maximum hold and thus offers a maximum load stability for the packages on the pallet.

Additional module MSK Anti-Collage - no gluing to product and sub packaging

Since the development of the MSK Anti-Collage-procedure for shrink machines; bonded PE packaging is a thing of the past - No need for an expensive separation-layer film.

Up to 40% energy savings with additional module MSK Covershrink

MSK shrink packaging systems can now be equipped or retrofitted with a newly developed and patent-pending additional module with which, depending on the film thickness and pallet format, up to 40% heat energy can be saved.

Choosing the right pallet packaging system:

Your product determines

In order to determine the optimal packaging procedures (stretch or shrink wrapping) we perform comparative tests with transport simulations at the MSK Customer Test Centre, together with our customers. This is the most reliable way to fact-based, product-specific advice.

Hybrid packaging systems for shrink wrapping and stretch wrapping

MSK offers so-called hybrid solutions, i.e.packaging systems which can automatically apply a shrink hood as well as a stretch hood to the pallets in mixed production and without loss of time.