The year 2022 is a special year for the glass industry as it is the Year of Glass! MSK served the glass industry since its founding in 1975. Becoming a brand in glass pallet shrink wrapping MSK is nowadays one of the leading suppliers for the entire Cold End equipment. As such, it is with pleasure that MSK celebrates with you this special year by accompanying you in your various Cold End projects. As a solid proof of its expertise and success in the field, MSK can count on various references from well-known companies in the world.

Let’s celebrate the Year of Glass 2022 with MSK – Your reliable & sustainable partner for Cold End equipment

2022 – The Year of Glass

Over the years, glass is a material that has gained in popularity for many reasons. Firstly, following the sanitary crisis, glass turned out to be a hygiene packaging alternative. Additionally, in the same period started a raw material crisis which has enhanced even more this sector. Last but not least, glass is above all a recyclable material, making it a sustainable packaging solution contributing to the protection of the environment. All the more reasons to dedicate a year to the glass industry!

Reliable & sustainable complete solutions for the Cold End

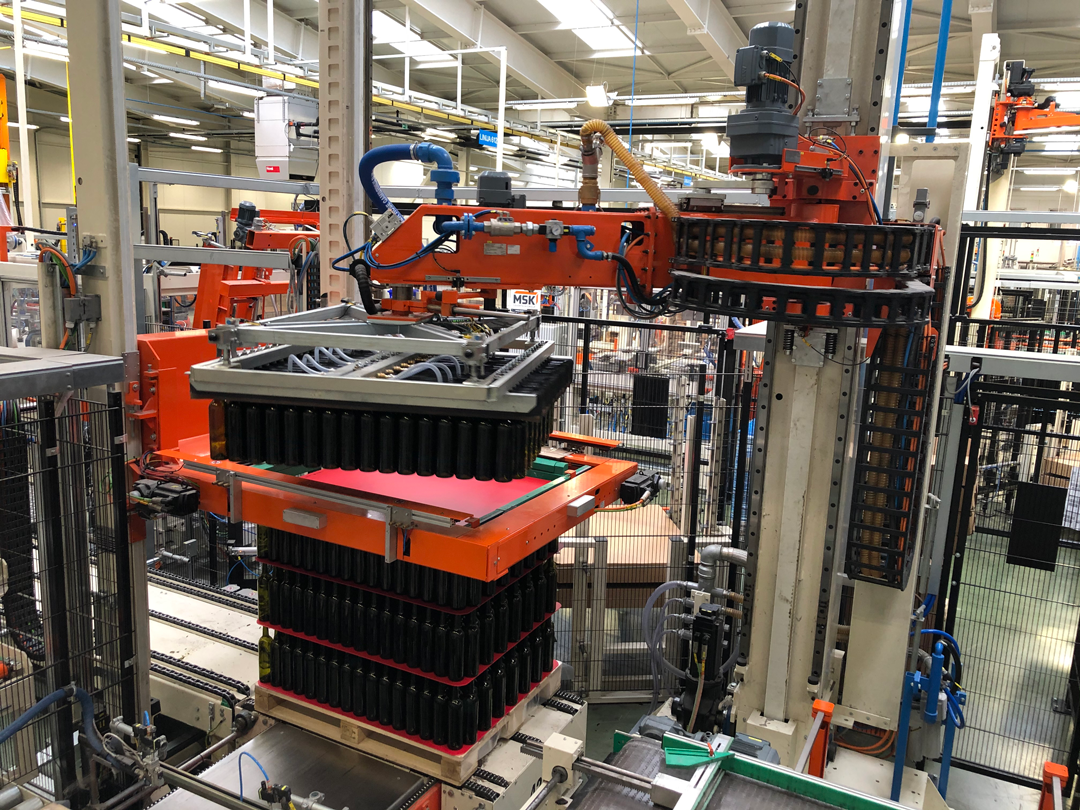

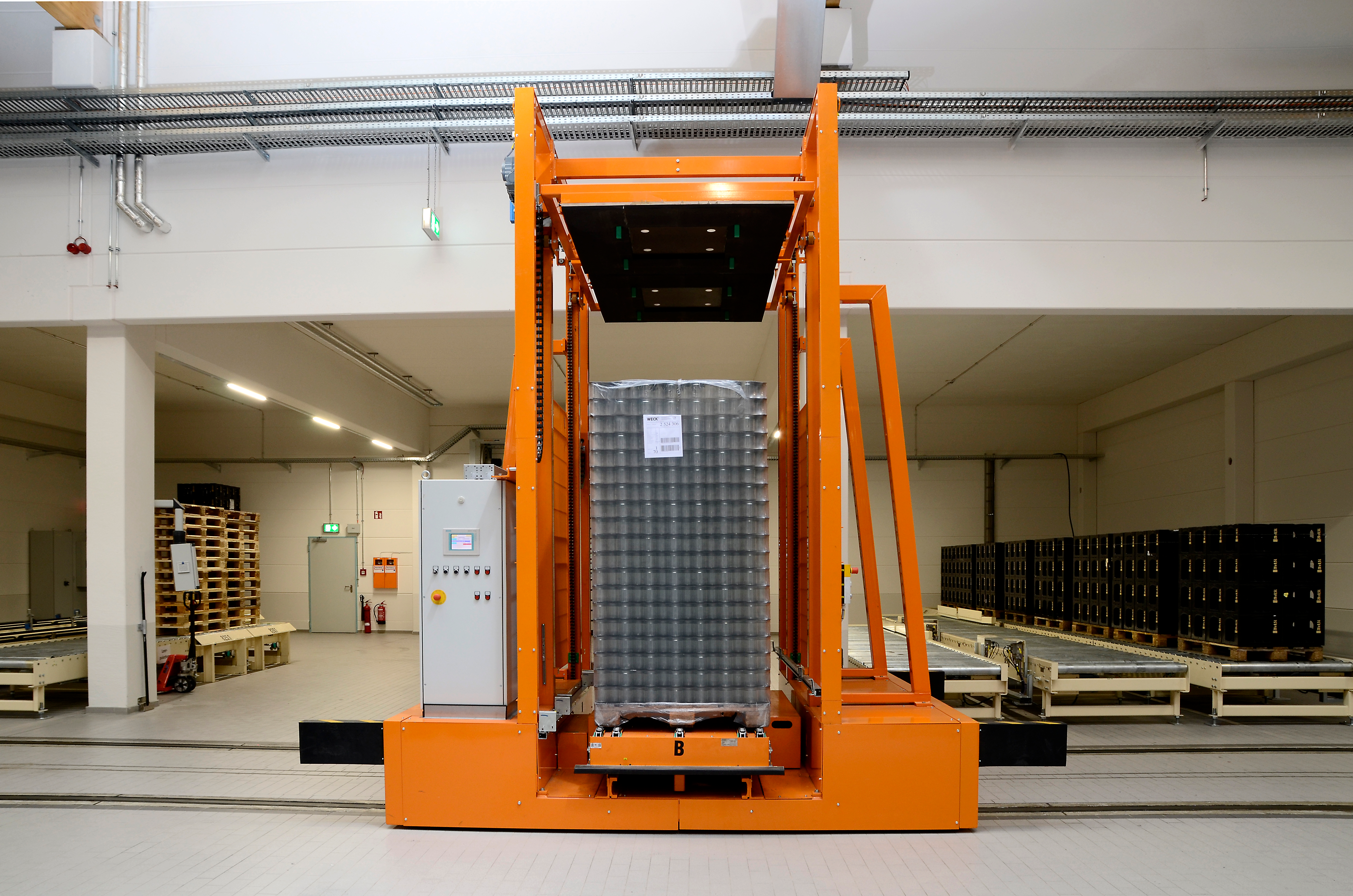

Sustainability has become more relevant than ever, playing a major role in increasing demand for glass containers. Machines must therefore be able to work efficiently while their demand for energy must drop significantly. To supply sustainable production solutions for the container glass industry, MSK has developed new technologies for the Cold End in the area of bottle conveyor systems, palletizing, packaging and pallet handling in general. Many MSK innovations thus attest to their commitment to sustainability.

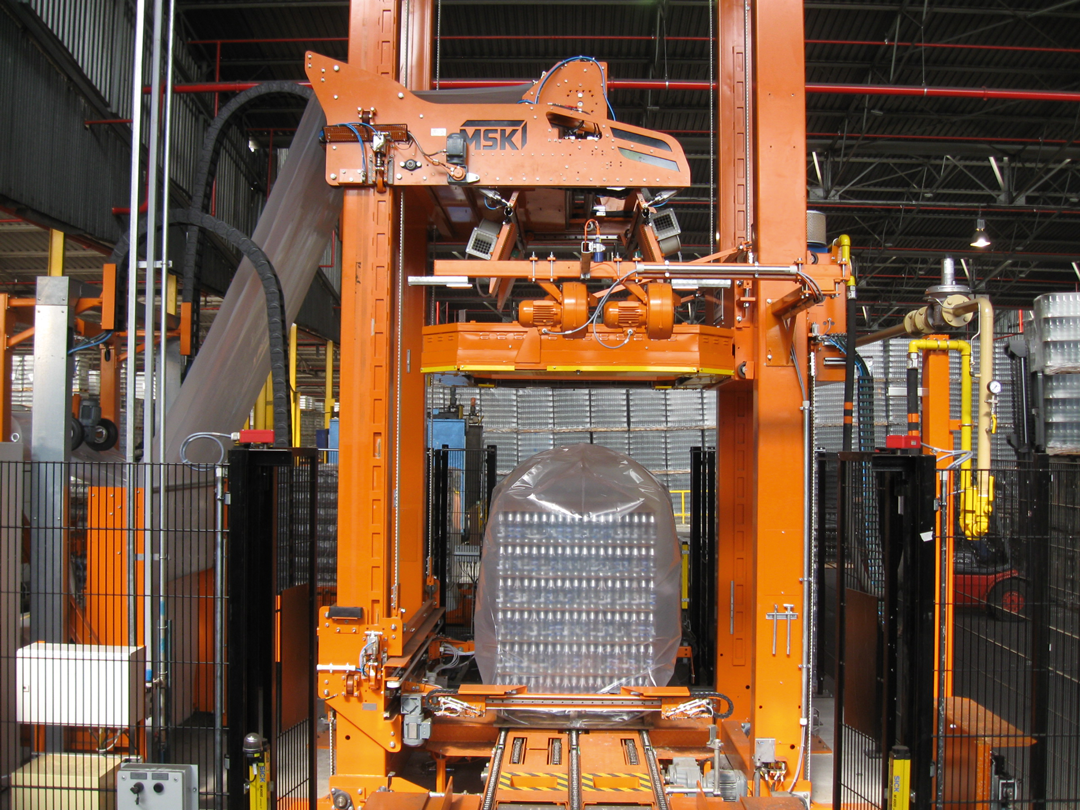

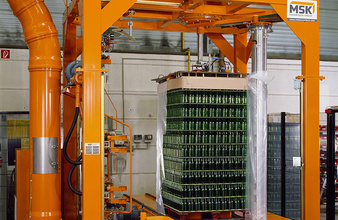

To begin with, MSK's original core business was the manufacturing of shrink wrapping machines. MSK was one of the first companies in this industry to produce shrink frame technology. Then, MSK Undershrink procedure was patented and allowed glass manufacturers to wrap its pallets with 20% thinner film. A glass company works 24h/7, 365 days per year. With an MSK machine lasting 20 years and wrapping 30 pallets/hour the estimated amounts of savings are incredible!

In a 20-year period companies can concretely reduce their film consumption by more than 600,000 kg. In addition to reducing their carbon footprint of more than 300,000 kg, MSK shrink packaging solutions have allowed glass manufacturers to save more than 160,000 m³ of natural gas. Such amounts are of course estimations that may vary across companies but is still a very good indication of how much savings are possible thanks to MSK. Concretely, MSK has sold nearly 800 shrink-wrap machines in the glass industry over the years – so let’s imagine how much savings has been made!

MSK continues to innovate as its newest generation of shrink-wrap machines reduces energy consumption effectively. But even before the most recent developments, the energy requirements of an MSK shrink frame were already around 10% below the average. Now the new generation of shrink frames lowers gas consumption by an additional 13%. MSK goes even further in terms of sustainability as an electric shrink frame, MSK Corritech was developed several years ago, allowing factories to stop using gas. It has been recently redesigned so to consume less energy while increasing efficiency.

In addition, the use of fuels for forklift operations are avoided thanks to MSK mobile pallet shuttle cars and AGVs.

To avoid the use of supplementary consumables that may be harmful to the environment, MSK designs its systems to avoid mixing materials and to ensure the most environmentally friendly consumption possible. For example, in places where there are constant vertical movements, motor capacity is reduced through the use of counterweights. Additionally, time belts instead of chains ensure a maintenance-free and hygienic operations.

Energy savings can be achieved on a case-by-case basis through the development of customized projects and solutions. Optimizations of the machine design contribute to a minimization of energy consumption through reducing the weight of moving parts.

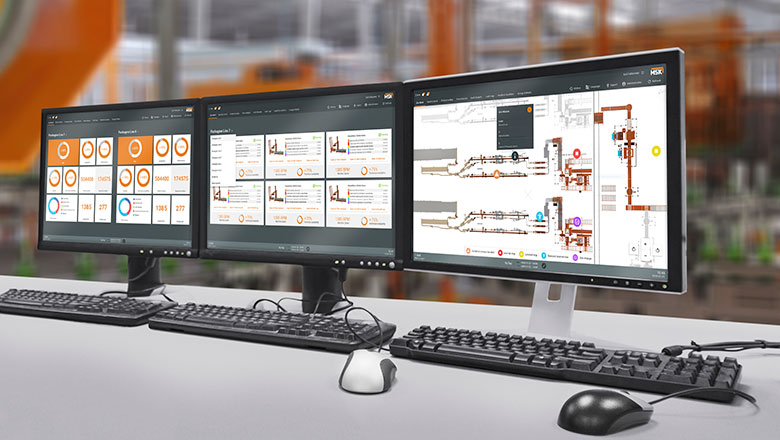

Sustainability supported by MSK's digital products

MSK's sustainability efforts are supported by their range of digital products. Sustainability is therefore increasingly made possible and visualized through the digitalization of processes. As such, with the latest digital MSK EMSY products, MSK systems can be monitored for energy and material consumption in real time using live figures and statistics.

Numerous references attest to MSK expertise

Thanks to decades of expertise and developments in Cold End equipment, MSK has acquired over the time a valued client portfolio made up of well-known brands in the sector.

Discover some special projects within the hollow glass industry:

- Case study Wiegand-Glas (Germany)

- Vidroporto report broadcasted on Brazilian TV (Brazil)

As proof of our expertise, serval significant glass projects are ongoing such as at Noelle von Campe, Allied Glass, Consol Glass Nigel, Vidroporto and many others.

Discover MSK installations for Cold End in action

If you are now curious to discover MSK solutions for Cold End in action, please have a look at MSK YouTube channel.

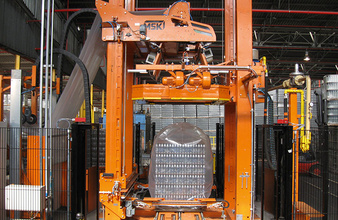

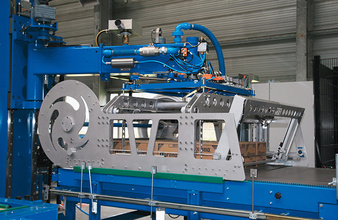

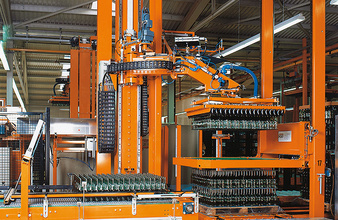

You can already enjoy discovering MSK main installations in pictures:

MSK – Your Cold End partner since 1975

As industry expert, MSK Covertech Group soon saw the potential of the glass industry back in 1975. Since then, the group has spent its energy in designing new concepts for this specific industry.

It is now MSK’s pride to offer to its customers in the Cold End complete solutions including palletizing, unwrapping, conveying, packaging systems and software solutions.

Some key inventions have marked MSK’s progress in the field:

2022-2012

2021

Energy-saving kit MSK Covershrink for shrink packaging machines

2020

Launching of the new MSK shrink frame generation making sustainable energy savings possible

2020

MSK EMSY smart app – App developed for mobile status monitoring of MSK installations

2020

MSK EMSY move – Mobile device allowing adjustment on MSK machines

2019

MSK palletizing systems now automatically adjustable – Allowing fast job change when working with different container glass types

2018

MSK EMSY analytics software – To connect all data of EMSY-controlled machines at the Cold End in the frame of the Industry 4.0

2015

Shrink packaging system - New generation of MSK Paratech

2011-1999

2011

MSK EMSY controls for the conveying of bottles

2009

New MSK Multitech generation, unique packaging machine with lowerable machine head

2008

Universal palletizing concept MSK Unitech allowing palletizing of bulk and cases without causing a stop during a shift change

1998-1988

1996

MSK Triotech glass palletizer - High-performance and high-complex palletizing system

1994

MSK Defotech unwrapping machine – A safe and high unpacking speed machine

1991

MSK Quintech glass palletizer – A high-performance palletizing system

For more information about MSK Cold End equipment, please write us at info@msk.de or call us at +49 (0) 2821 506-0. We will be happy to advise you!

Follow MSK’s Year of Glass posts on LinkedIn.

Find MSK’s Cold End solutions in action on YouTube.